Introducing Flat-Rate B18 Twin Turbo (56k not today)

#1

After the longest week I have ever worked on one single project in my entire life. First off I

want to say thanks to everyone before I start off..

Thanks to:

Lionel @ CNR for lots of welding

Beau - Always helping me out, DP's look great man

Cadracer (ted) - for helping me when I get so frustrated and want to give up.. HMT is

here because of you!

Travis - Thanks for all the little odds and ends and helping me put the engine in!

Dustin - Ahh, saved my *** on a few little parts, pistons, oil return flanges and some

labor. oh and thanks for the coke

Sam @ BMC Racing, for all the flanges, they were all pretty good. I'm very impressed you

could make those flanges with just pictures I sent you. The DP flanges were a little off, but

nothing a die grinder couldnt handle

Tyrus @ Johnnyracecar, The intercooler is sexy man.. fitment was a huge pain in the ***,

but its ------- in there, and if I wreck the car I think I'm going to die, I had to hack

everything!

PNK team Larry, Ron, Gil (the big crew) for giving me a hand on little things, and

letting me trash your ------- bays on my 2 days off haha.

And if I forgot someone, sorry I love you too..

The Twin Turbo Ls/Vtec

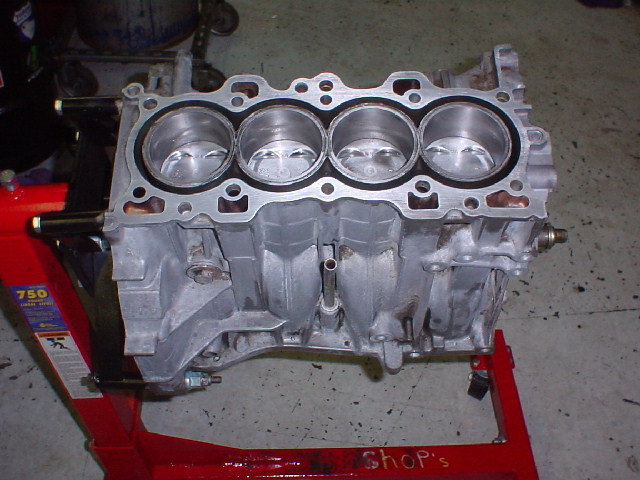

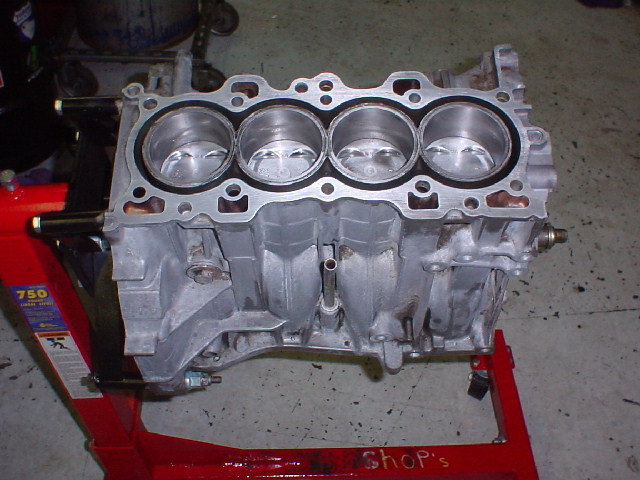

Starting off Sunday night 4/4. I drove down to Tacoma to pic this LS shortblock up from Colten

(45psi) It was Onyx's old block from his integra with very high milage.

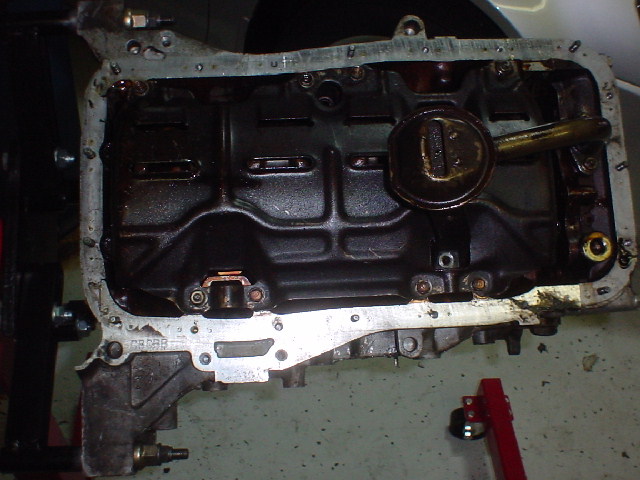

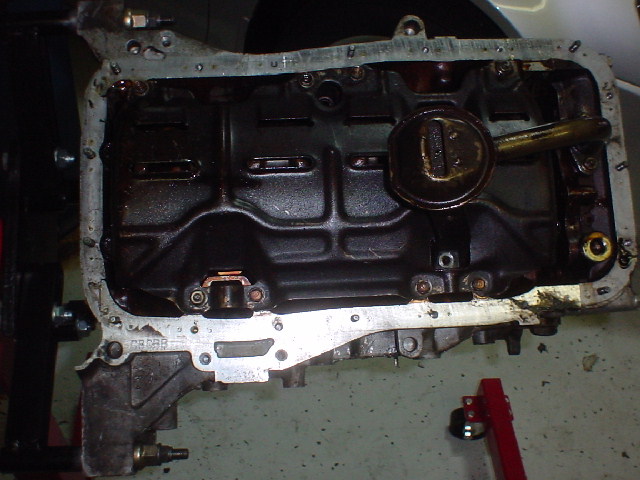

The block was just caked with built up oil, Heavy build up

The guy had overfilled the oil and was raping it and it ended up bending a rod.

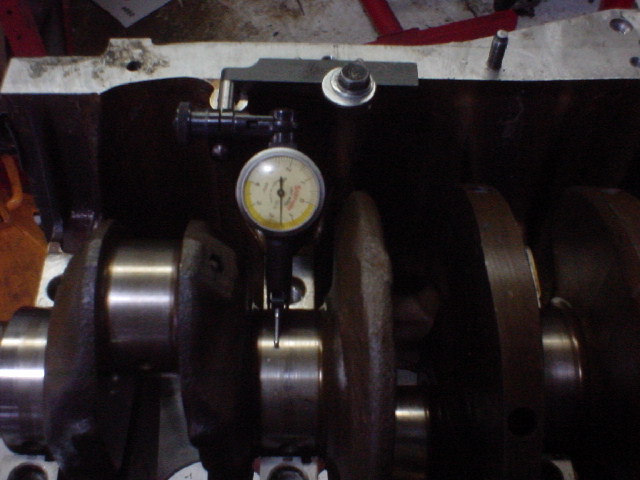

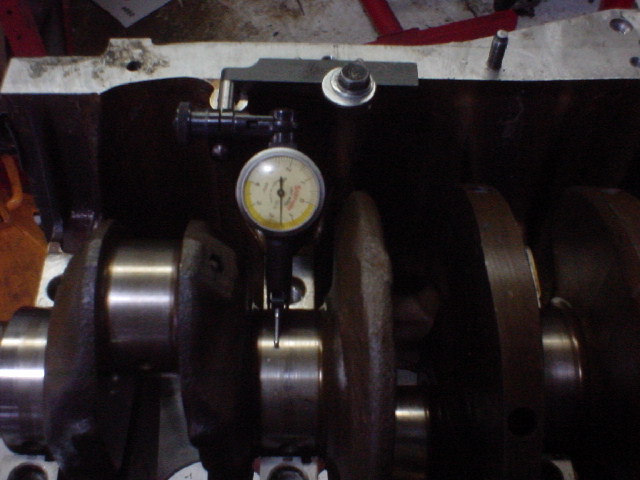

Started to tear down the engine on Monday, after inspecting the main bearings I was a little

freaked out, they had some really odd wear patterns like nothing I've seen before. Probably due

to the bent rod. I had suspected that the crank was bent. Using a Dial indicator, I checked it

and it was fine. Dont wanna be spinning 8500rpms with a bent crank

Normally if this was an engine I cared about, I would put a nice set of factory bearings in this

thing, but I didnt have time for special order bearings, and the price of factory bearings are

spendy.

So we went with a nice ------- cheap set of Napa Main bearings for 22 bucks, hah. Standard

bearings in a honda? like ya.. no such thing

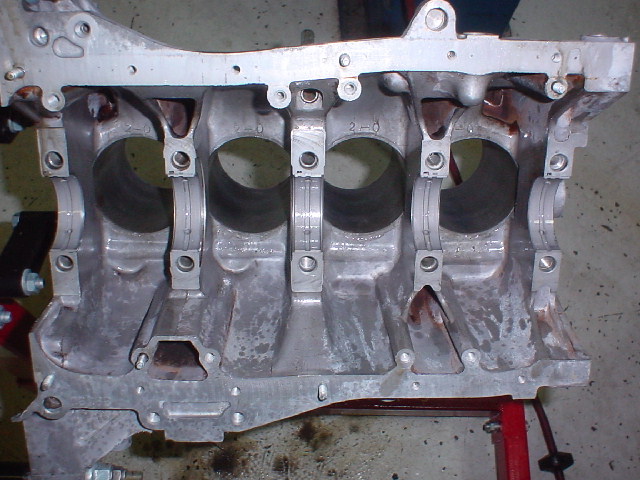

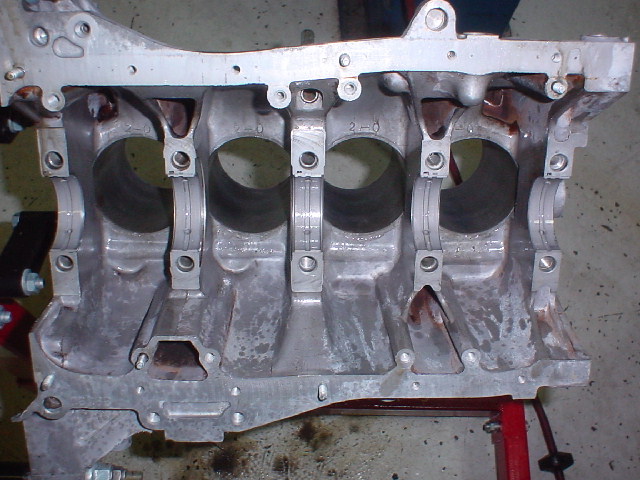

As you can see I steamed the living ---- out of the block with acid and degreaser. It came out

really clean.

Sunday Night I also picked up my Old B18b rods/pistons from my old ls/vtec turbo. Dustin had

them sitting in his garage forever. Thanks dude! bearings were in perfect shape.

I also went with a nice set of cheapy rings through worldpac. I think they were like 28 bucks?

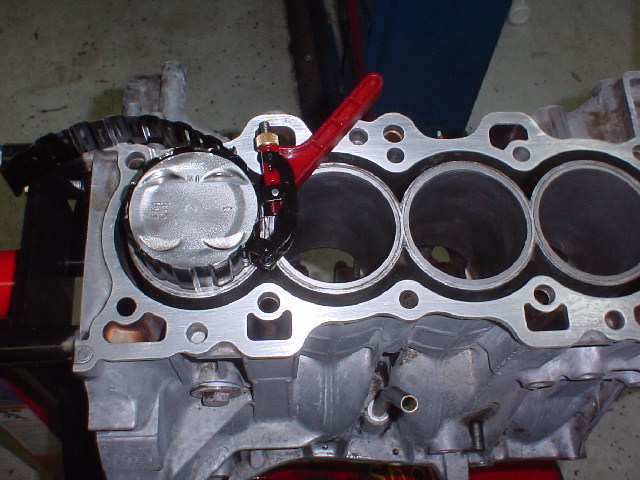

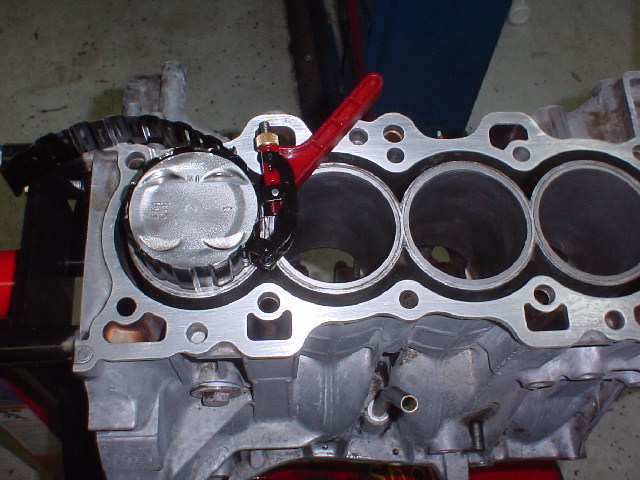

Note: the cheapy piston installer, some people think these things are ------- shitty. I have

never used such an easy ring compressor, no broken rings and goes in perfect everytime.

I gave the block a quick hone job to give it a nice cross hatch. (hence the word quick) flat

rate style..

Flat rate style ment checking bearings tolerneces on 1 cylinder and that was it, haha. I checked

1 main and 1 rod, they looked good. So ::crosses fingers:: shouldnt knock, well not right now

anyways.

Monday the entire shortblock was completed, so tuesday I chopped the intake manifold in half and

had my buddy lionel weld on a big tube (large plenum) I spent the day smoothing out the runners.

Bling bling! came out real nice inside, brang it back to him later on that day to get the other

half welded back on.

Tuesday Night I ripped the Trailerpark B16a head off, and I mean fast.. I had the head off in

less than 15 mins and the car pushed out. I'm not trying to brag, but god damn... I couldnt

beleive it, haha... The guys in the shop were like WTF? you just drove it in, now your pushing

it out?

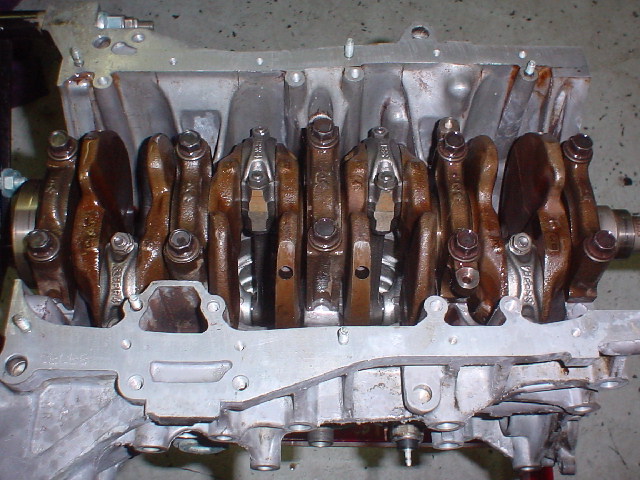

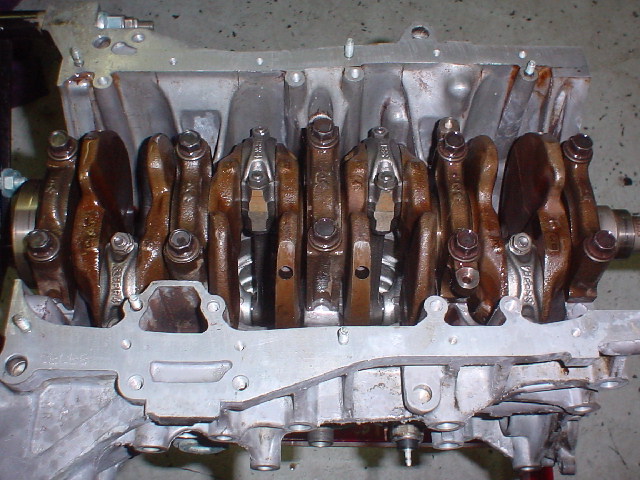

Wed, I started working on the head, it really needed some attention. I got this head (and b16a

longblock) for doing a motor swap. The exhaust valves were beat very hard.

I went ahead and lapped the ---- out of the valves and cleaned all the carbon off them. Normally

I'd just spit the money out for a full valve grind, but I didnt have time nor the money.

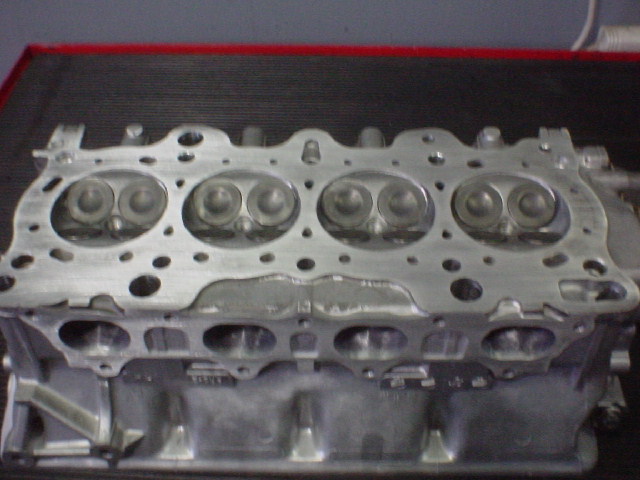

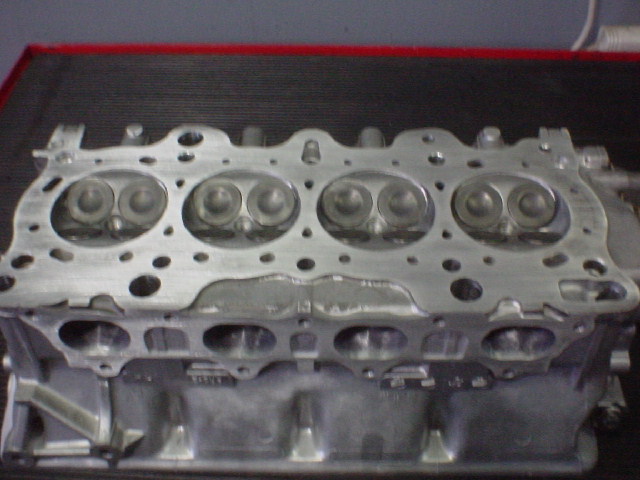

In order to make a Vtec head fit on a non-vtec block you have to bore out the dowl pin holes,

Normally I'd just take this to my buddies house and use his drill press or buy those nifty

fittings from GE, again.. that money time factor comes into play.. I borrowed a huge *** drill

bit that was designed for a press that I had to grind down to even fit in my drill, so lets just

say... it wasnt so precise, hahah

Again another mod for the vtec head, you have to block this oil passage, just used a steel 1/8th

NPT plug

Since the head was off, and all the valves were out I wanted to spend some time on the head. Clean up

some of the casting flaws and do some minor porting. Spent a few hours on it.

Finally the head is done

Late Wed Night I started to put this thing together, I was running into all kinds of missing

parts, god damn onyx stripped this block ------- clean.

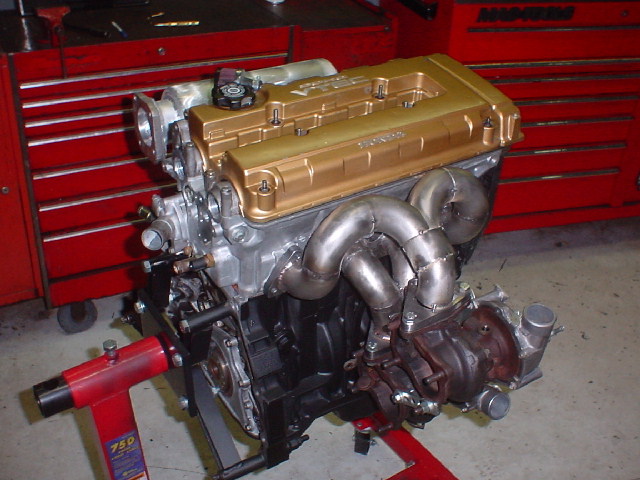

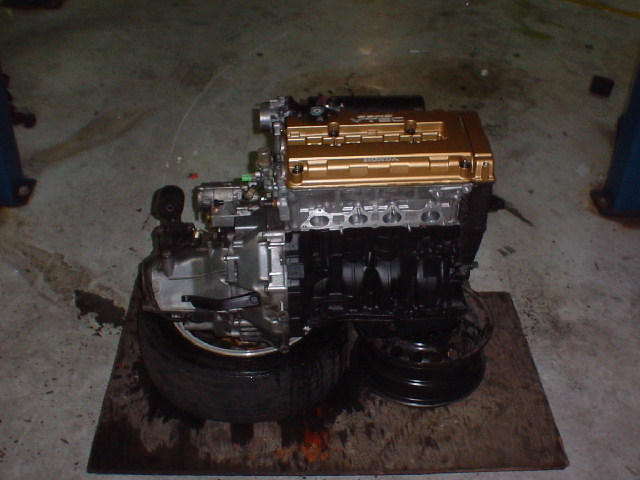

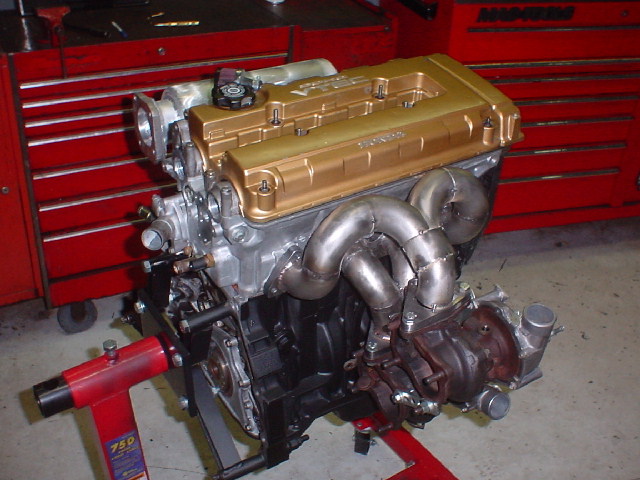

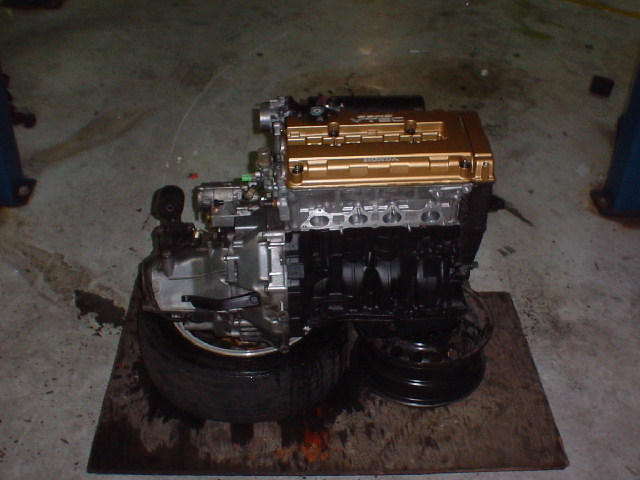

I decidied as much as I like to stare at my ITR cams on my computer desk, I wanted to see how

they worked in something. Also decided to paint the block flat black, nobody liked this idea,

but I dont care.. It hides oil leaks!

End of Wed Night I had both manifolds all mocked up, using stainless steel weld el's from

mcmaster.com, run about 4.20 a piece and used about 8 of them. Even thought I didnt do the

welding on it, I thought I didnt pretty good for mocking up my first manifold like this =)

Thursday Morning I got the manifold back from lionel all welded up and ready to go, I started

working on the oil feed. I was going to use some nice stainless lines with -an fittings. But it

wouldnt be HMT without the Barb'd oil fittings, heh. I didnt have the right banjo fitting So I

robbed one off a 3000gt slave cylinder, lucky find.

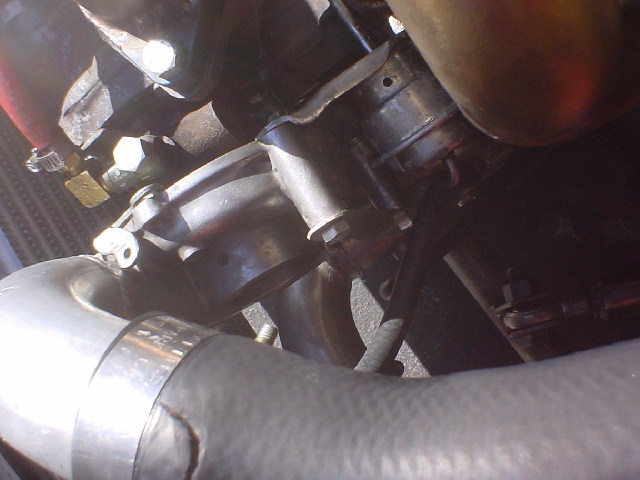

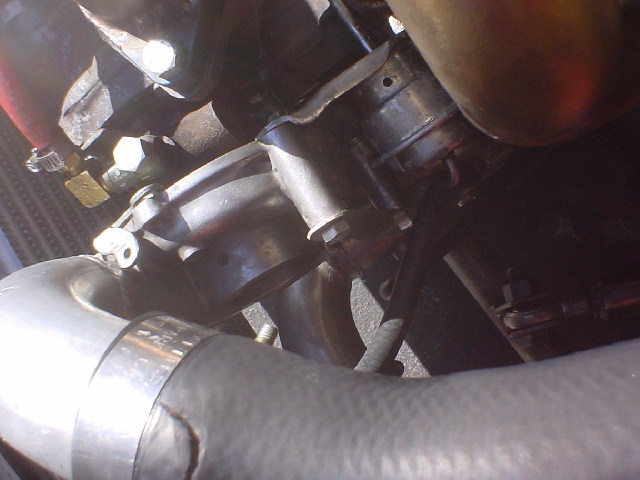

Oil return was was pretty basic, I planned on merging both oil returns into one. This fitting

got all fucked up after the project was done I didnt do a good job welding the backside leaks

leaks

like a mother ******, Gotta fix that.

Finally we got a local supplier with Mandrel bends (INSTOCK!) beau hooked me up, with 3 2.5's

and 1 3.0 for dirt cheap.

I've been using the same Upper IC charge pipe on the last 5 setups in my car, and it looked like

the most fucked up mangled piece of ---- known to man kind, (shown behind) So it was time for a

new upper IC pipe, found a perfect hole saw for putting my Tial BOV flange in.

Thursday I waited for beau to get off work to help me with the downpipes, so I decidied to work on my built ls/vtec and start doing a little bit of work on it too, just to kill some time.

Got my head back from the machine shop with all 1mm oversize stainless steel valves, titanium

retainers, duel valve springs, looked pretty! I went ahead and torqued the head on.

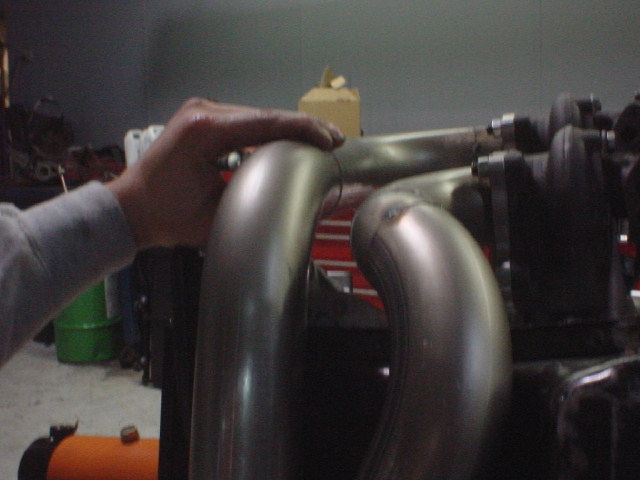

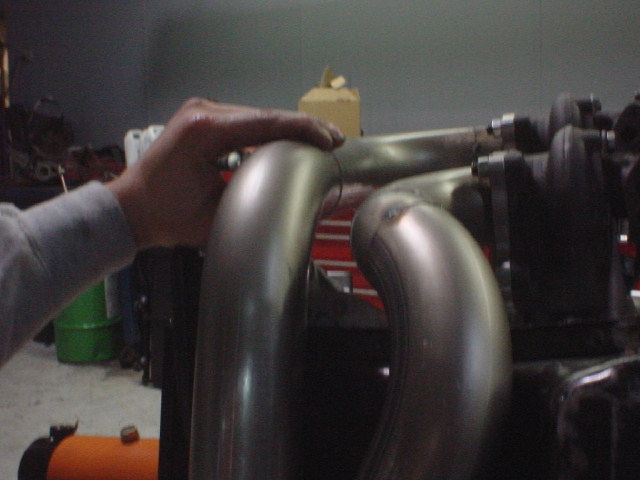

Beau Working on the downpipes, I really wanted to go for something simple, like a 2 1/2 from the top

turbo dump right into the bottom 2.5 dp.

We used my built ls/vtec to mock the setup on, while I was still doing some final stuff to the

FL Ls/Vtec.

Of course Beau had to get a little wild on the Downpipes, I walked over, and was like... whoa!

Nice job dude, Both pipes come down under the pan and merge into a 3in collector and doglag's

left.

Copyright Downpipe **** Shot... by Garrison Gerth

Thursday night was a ------- late one.. I pulled the Trailerpark B16a out of my car and pitched

that ****** in the side of the shop. I glanced at the cylinder walls and just shook my head. The

block is so fucked up.

Late Late Thursday night I'm freaking out because some guy took the cherry picker home and I

couldnt get the freaking engine off the engine stand by myself, buddy travis to the rescue.

Thanks man!

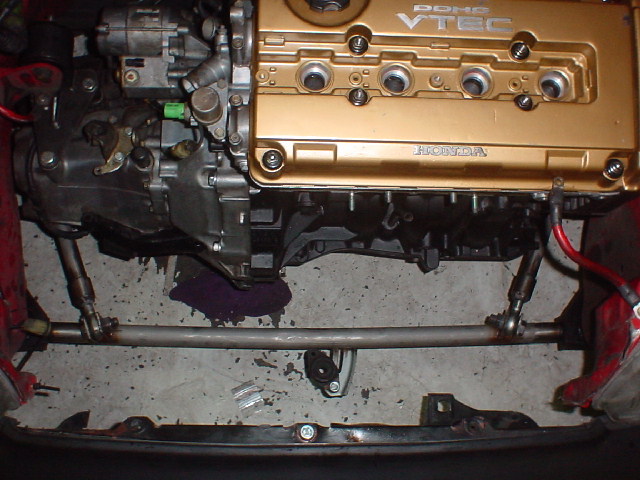

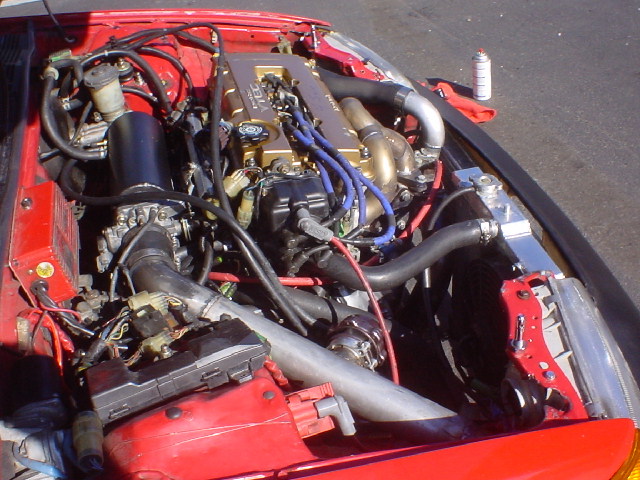

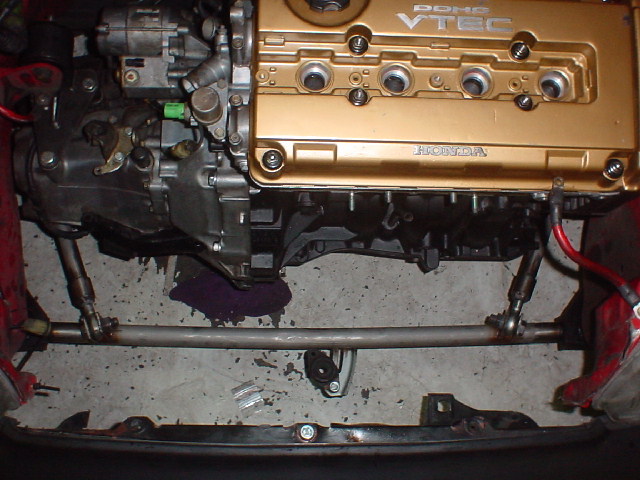

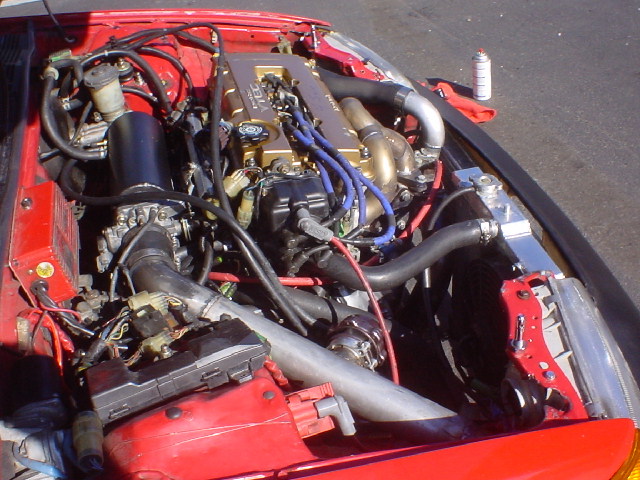

Putting engines in from the bottom is so nice with a lift

You can see the custom X member Beau made for me awhile back. All done in stainlless steel, &

adjustable (ya thats a alternator bracket as a my radiator bracket) hah

Friday Night Beau had the dP's all welded up, and I was doing test fits with the intercooler. I

forgot my camra this day and was in such a hurry to get this thing done. Dustin, Travis, Beau

all came to help to get this thing done.

Charge pipes were a hoe, the duel inlet on the intercooler was a very bad idea, and wish it was

setup like a normal intercooler.

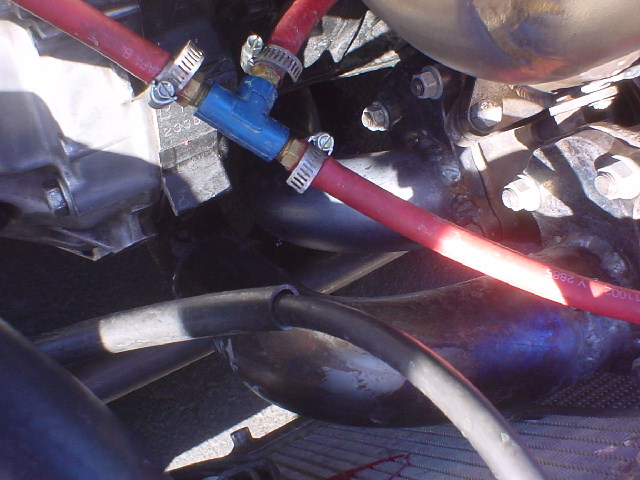

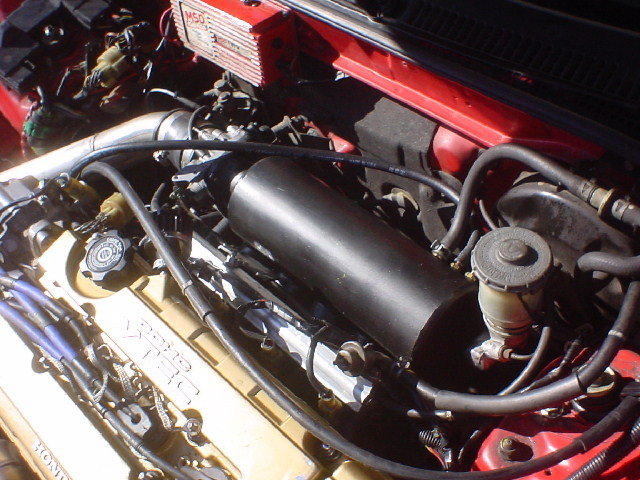

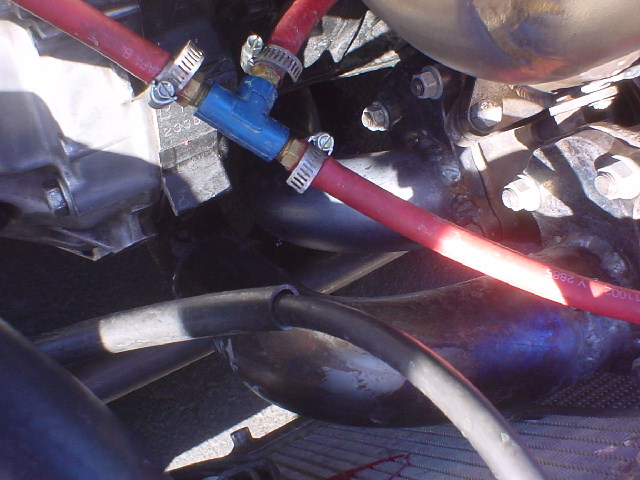

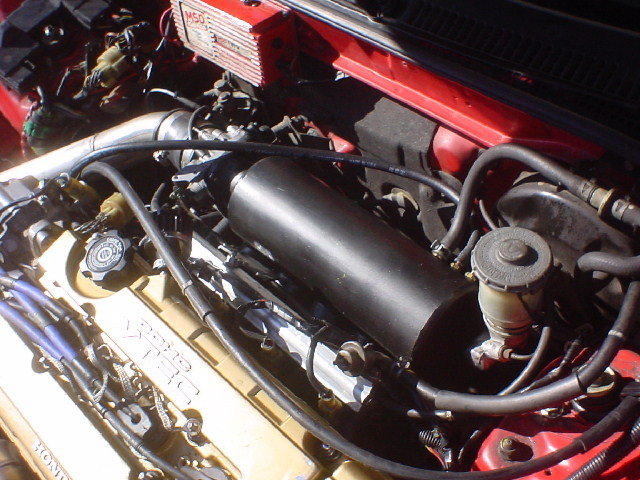

Oil feed was setup with a tuner toyz fitting off the back of the block, to another T, 1 for the

head, and 1 for the turbo. Then the Turbo feed got split off again. All using 1/8th NPT

fittings. Shitty *** NAPA sold out of my favorite black hose I normally use and hand to use some

homo *** red high pressure hose.

Friday everything was in and running, it ran like complete ---- at first, Oil was coming out of

the turbos really bad, coolant was blowing out of the back of the block, and I had 2 foot flames

coming out of the downpipe. OMG, hahah

Anyways the o-ring seal on the back of the block (tube that runs to the water pump blew out) So

after replacing that twice.. it was fixed. And the the oil was because the dipstick wasnt in,

!~!!!!! The PR3 map I had a real heavy enrichment at cold startup so I dont think it liked it.

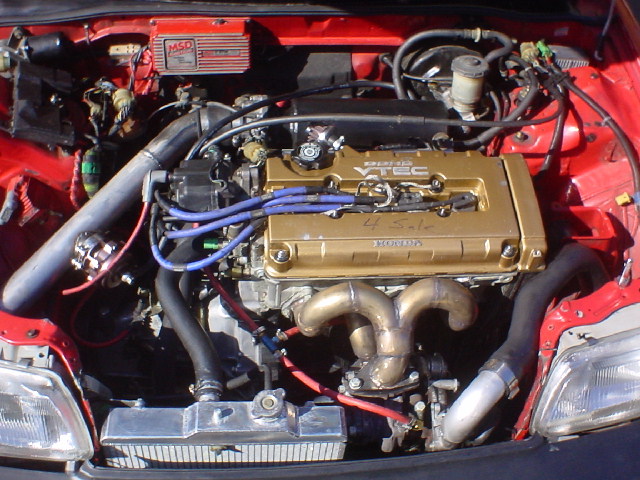

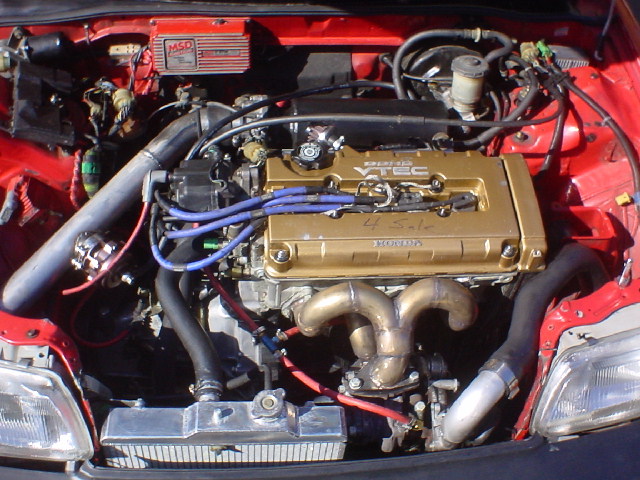

Completed.... =) Saturday Morning, I wanted to get this thing done for a local honda-tech meet,

and for some local street racers saying that I was talking bullshit about a TT setup. You should

of seen the peoples faces at the honda-tech meet. One guy asked "Who brand manifold is that" I

told him it was a Drag Gen 7 beta 2b. rofl

Yes, it fits, Yes it runs.. The questions Is it fast? I'd say so. Honestly, I've never had a

turbo setup sound like this. It sounds really werid, almost like my Buddies Rotary. I've drove

lots of turbo hondas open DP, but nothing like this. Boost comes in incredibly fast, way faster

than I thought. Spools 5psi around 2800rpms, and holds 7psi all the way to 8300. When the ITR

cams kick in, the thing gets pretty wild. I'm running my old ls/vtec turbo spark & fuel map.

Seems to be running pretty good but needs lots of minor adjustments. Coolant leaks probably that

(coughusedheadgasketcough) and the oil leaks from the return pretty bad. Thats what you get

and the oil leaks from the return pretty bad. Thats what you get

when you flatrate ----.

Another shot.. yes its very cluttered right now, plus I had a little incident with coolant

blowing everywhere, onyx left the coolant drain plug loose and I didnt check it

I dont care whatcha guys say.. I like flat black... btw, can you see the welds on the intake

mani? Lionel ground them down flush and you cant even see them. Looks great! Only 1 flaw in this

manifold design and the end cap wasnt rounded (bulged out) instead it was just capped off.

Overall it was a fun setup, would I do it again? No.. lots of people kept saying "what a waste

of money" well, this entire setup didnt cost me much at all, I get lots of little perks from HMT

so it lets me do this kinds of stuff on a cheap level.

What am I expecting of this? Well I'm sure I'll dyno it, and see if I can get 300whp out of it,

maybe rape it around a bit more, save some money and finish up my built ls/vtec and put on my

62-1.

Best quote of the entire week.

"Man it feels good to rub the soap bar between your nuts when they are all sticky" -BG

Feels good to take a shower and relax...

Enjoy the pics guys (I know its long) and fire away with the questions

Jeff Frank

Btw, whitey... watch out I have a thread to compete with your 20,000 views

*** Edit ***

285whp / 191tq @ 8-12psi

Pretty good for a stock engine that was all slapped together. Generall ls/vtecs NA make about 170ish whp NA, so this was about a 110whp gain. My old ls/vtec single turbo dynoed @ 272whp with 12psi. The setups are very very comparable.

**Dyno Video** Right Click save as

http://www.draglab.com/media/HMTDyno5-25-04.wmv

And for the people who keep saying "wow what a waste of money and time" lets see the turbo kit cost me nearly nothing.

Intercooler - Free

6 mandrel bends stainless bends - $40

Oil feed/Return from Napa - $35

Flanges from BMC - Free

2 180 2.5 Mandrel DP - $25

o2 Bung - $5

Rhb5 Turbos (2) From Pull-a-part - $40.00

Tial 50mm BOV & IC piping (all from previous setups)

So Basically under $200 bucks I have in the turbokit

& the Engine Rebuild

B18 Shortblock $100

B18b Pistons/rods $50

ITR Cams - Trade

Napa Rings/Bearnings/HG $100

B16a Custom Intake modified $75

And all the rest of the stuff I already had from previous setups. So, around 400 bucks for the quicky rebuild.

Total Labor 7 days (4-5 hours each day)

35hrs

700 Dollars my cost

Waste of time? I dont think so.. Blow me :P

want to say thanks to everyone before I start off..

Thanks to:

Lionel @ CNR for lots of welding

Beau - Always helping me out, DP's look great man

Cadracer (ted) - for helping me when I get so frustrated and want to give up.. HMT is

here because of you!

Travis - Thanks for all the little odds and ends and helping me put the engine in!

Dustin - Ahh, saved my *** on a few little parts, pistons, oil return flanges and some

labor. oh and thanks for the coke

Sam @ BMC Racing, for all the flanges, they were all pretty good. I'm very impressed you

could make those flanges with just pictures I sent you. The DP flanges were a little off, but

nothing a die grinder couldnt handle

Tyrus @ Johnnyracecar, The intercooler is sexy man.. fitment was a huge pain in the ***,

but its ------- in there, and if I wreck the car I think I'm going to die, I had to hack

everything!

PNK team Larry, Ron, Gil (the big crew) for giving me a hand on little things, and

letting me trash your ------- bays on my 2 days off haha.

And if I forgot someone, sorry I love you too..

The Twin Turbo Ls/Vtec

Starting off Sunday night 4/4. I drove down to Tacoma to pic this LS shortblock up from Colten

(45psi) It was Onyx's old block from his integra with very high milage.

The block was just caked with built up oil, Heavy build up

The guy had overfilled the oil and was raping it and it ended up bending a rod.

Started to tear down the engine on Monday, after inspecting the main bearings I was a little

freaked out, they had some really odd wear patterns like nothing I've seen before. Probably due

to the bent rod. I had suspected that the crank was bent. Using a Dial indicator, I checked it

and it was fine. Dont wanna be spinning 8500rpms with a bent crank

Normally if this was an engine I cared about, I would put a nice set of factory bearings in this

thing, but I didnt have time for special order bearings, and the price of factory bearings are

spendy.

So we went with a nice ------- cheap set of Napa Main bearings for 22 bucks, hah. Standard

bearings in a honda? like ya.. no such thing

As you can see I steamed the living ---- out of the block with acid and degreaser. It came out

really clean.

Sunday Night I also picked up my Old B18b rods/pistons from my old ls/vtec turbo. Dustin had

them sitting in his garage forever. Thanks dude! bearings were in perfect shape.

I also went with a nice set of cheapy rings through worldpac. I think they were like 28 bucks?

Note: the cheapy piston installer, some people think these things are ------- shitty. I have

never used such an easy ring compressor, no broken rings and goes in perfect everytime.

I gave the block a quick hone job to give it a nice cross hatch. (hence the word quick) flat

rate style..

Flat rate style ment checking bearings tolerneces on 1 cylinder and that was it, haha. I checked

1 main and 1 rod, they looked good. So ::crosses fingers:: shouldnt knock, well not right now

anyways.

Monday the entire shortblock was completed, so tuesday I chopped the intake manifold in half and

had my buddy lionel weld on a big tube (large plenum) I spent the day smoothing out the runners.

Bling bling! came out real nice inside, brang it back to him later on that day to get the other

half welded back on.

Tuesday Night I ripped the Trailerpark B16a head off, and I mean fast.. I had the head off in

less than 15 mins and the car pushed out. I'm not trying to brag, but god damn... I couldnt

beleive it, haha... The guys in the shop were like WTF? you just drove it in, now your pushing

it out?

Wed, I started working on the head, it really needed some attention. I got this head (and b16a

longblock) for doing a motor swap. The exhaust valves were beat very hard.

I went ahead and lapped the ---- out of the valves and cleaned all the carbon off them. Normally

I'd just spit the money out for a full valve grind, but I didnt have time nor the money.

In order to make a Vtec head fit on a non-vtec block you have to bore out the dowl pin holes,

Normally I'd just take this to my buddies house and use his drill press or buy those nifty

fittings from GE, again.. that money time factor comes into play.. I borrowed a huge *** drill

bit that was designed for a press that I had to grind down to even fit in my drill, so lets just

say... it wasnt so precise, hahah

Again another mod for the vtec head, you have to block this oil passage, just used a steel 1/8th

NPT plug

Since the head was off, and all the valves were out I wanted to spend some time on the head. Clean up

some of the casting flaws and do some minor porting. Spent a few hours on it.

Finally the head is done

Late Wed Night I started to put this thing together, I was running into all kinds of missing

parts, god damn onyx stripped this block ------- clean.

I decidied as much as I like to stare at my ITR cams on my computer desk, I wanted to see how

they worked in something. Also decided to paint the block flat black, nobody liked this idea,

but I dont care.. It hides oil leaks!

End of Wed Night I had both manifolds all mocked up, using stainless steel weld el's from

mcmaster.com, run about 4.20 a piece and used about 8 of them. Even thought I didnt do the

welding on it, I thought I didnt pretty good for mocking up my first manifold like this =)

Thursday Morning I got the manifold back from lionel all welded up and ready to go, I started

working on the oil feed. I was going to use some nice stainless lines with -an fittings. But it

wouldnt be HMT without the Barb'd oil fittings, heh. I didnt have the right banjo fitting So I

robbed one off a 3000gt slave cylinder, lucky find.

Oil return was was pretty basic, I planned on merging both oil returns into one. This fitting

got all fucked up after the project was done I didnt do a good job welding the backside

leaks

leaks like a mother ******, Gotta fix that.

Finally we got a local supplier with Mandrel bends (INSTOCK!) beau hooked me up, with 3 2.5's

and 1 3.0 for dirt cheap.

I've been using the same Upper IC charge pipe on the last 5 setups in my car, and it looked like

the most fucked up mangled piece of ---- known to man kind, (shown behind) So it was time for a

new upper IC pipe, found a perfect hole saw for putting my Tial BOV flange in.

Thursday I waited for beau to get off work to help me with the downpipes, so I decidied to work on my built ls/vtec and start doing a little bit of work on it too, just to kill some time.

Got my head back from the machine shop with all 1mm oversize stainless steel valves, titanium

retainers, duel valve springs, looked pretty! I went ahead and torqued the head on.

Beau Working on the downpipes, I really wanted to go for something simple, like a 2 1/2 from the top

turbo dump right into the bottom 2.5 dp.

We used my built ls/vtec to mock the setup on, while I was still doing some final stuff to the

FL Ls/Vtec.

Of course Beau had to get a little wild on the Downpipes, I walked over, and was like... whoa!

Nice job dude, Both pipes come down under the pan and merge into a 3in collector and doglag's

left.

Copyright Downpipe **** Shot... by Garrison Gerth

Thursday night was a ------- late one.. I pulled the Trailerpark B16a out of my car and pitched

that ****** in the side of the shop. I glanced at the cylinder walls and just shook my head. The

block is so fucked up.

Late Late Thursday night I'm freaking out because some guy took the cherry picker home and I

couldnt get the freaking engine off the engine stand by myself, buddy travis to the rescue.

Thanks man!

Putting engines in from the bottom is so nice with a lift

You can see the custom X member Beau made for me awhile back. All done in stainlless steel, &

adjustable (ya thats a alternator bracket as a my radiator bracket) hah

Friday Night Beau had the dP's all welded up, and I was doing test fits with the intercooler. I

forgot my camra this day and was in such a hurry to get this thing done. Dustin, Travis, Beau

all came to help to get this thing done.

Charge pipes were a hoe, the duel inlet on the intercooler was a very bad idea, and wish it was

setup like a normal intercooler.

Oil feed was setup with a tuner toyz fitting off the back of the block, to another T, 1 for the

head, and 1 for the turbo. Then the Turbo feed got split off again. All using 1/8th NPT

fittings. Shitty *** NAPA sold out of my favorite black hose I normally use and hand to use some

homo *** red high pressure hose.

Friday everything was in and running, it ran like complete ---- at first, Oil was coming out of

the turbos really bad, coolant was blowing out of the back of the block, and I had 2 foot flames

coming out of the downpipe. OMG, hahah

Anyways the o-ring seal on the back of the block (tube that runs to the water pump blew out) So

after replacing that twice.. it was fixed. And the the oil was because the dipstick wasnt in,

!~!!!!! The PR3 map I had a real heavy enrichment at cold startup so I dont think it liked it.

Completed.... =) Saturday Morning, I wanted to get this thing done for a local honda-tech meet,

and for some local street racers saying that I was talking bullshit about a TT setup. You should

of seen the peoples faces at the honda-tech meet. One guy asked "Who brand manifold is that" I

told him it was a Drag Gen 7 beta 2b. rofl

Yes, it fits, Yes it runs.. The questions Is it fast? I'd say so. Honestly, I've never had a

turbo setup sound like this. It sounds really werid, almost like my Buddies Rotary. I've drove

lots of turbo hondas open DP, but nothing like this. Boost comes in incredibly fast, way faster

than I thought. Spools 5psi around 2800rpms, and holds 7psi all the way to 8300. When the ITR

cams kick in, the thing gets pretty wild. I'm running my old ls/vtec turbo spark & fuel map.

Seems to be running pretty good but needs lots of minor adjustments. Coolant leaks probably that

(coughusedheadgasketcough)

and the oil leaks from the return pretty bad. Thats what you get

and the oil leaks from the return pretty bad. Thats what you get when you flatrate ----.

Another shot.. yes its very cluttered right now, plus I had a little incident with coolant

blowing everywhere, onyx left the coolant drain plug loose and I didnt check it

I dont care whatcha guys say.. I like flat black... btw, can you see the welds on the intake

mani? Lionel ground them down flush and you cant even see them. Looks great! Only 1 flaw in this

manifold design and the end cap wasnt rounded (bulged out) instead it was just capped off.

Overall it was a fun setup, would I do it again? No.. lots of people kept saying "what a waste

of money" well, this entire setup didnt cost me much at all, I get lots of little perks from HMT

so it lets me do this kinds of stuff on a cheap level.

What am I expecting of this? Well I'm sure I'll dyno it, and see if I can get 300whp out of it,

maybe rape it around a bit more, save some money and finish up my built ls/vtec and put on my

62-1.

Best quote of the entire week.

"Man it feels good to rub the soap bar between your nuts when they are all sticky" -BG

Feels good to take a shower and relax...

Enjoy the pics guys (I know its long) and fire away with the questions

Jeff Frank

Btw, whitey... watch out I have a thread to compete with your 20,000 views

*** Edit ***

285whp / 191tq @ 8-12psi

Pretty good for a stock engine that was all slapped together. Generall ls/vtecs NA make about 170ish whp NA, so this was about a 110whp gain. My old ls/vtec single turbo dynoed @ 272whp with 12psi. The setups are very very comparable.

**Dyno Video** Right Click save as

http://www.draglab.com/media/HMTDyno5-25-04.wmv

And for the people who keep saying "wow what a waste of money and time" lets see the turbo kit cost me nearly nothing.

Intercooler - Free

6 mandrel bends stainless bends - $40

Oil feed/Return from Napa - $35

Flanges from BMC - Free

2 180 2.5 Mandrel DP - $25

o2 Bung - $5

Rhb5 Turbos (2) From Pull-a-part - $40.00

Tial 50mm BOV & IC piping (all from previous setups)

So Basically under $200 bucks I have in the turbokit

& the Engine Rebuild

B18 Shortblock $100

B18b Pistons/rods $50

ITR Cams - Trade

Napa Rings/Bearnings/HG $100

B16a Custom Intake modified $75

And all the rest of the stuff I already had from previous setups. So, around 400 bucks for the quicky rebuild.

Total Labor 7 days (4-5 hours each day)

35hrs

700 Dollars my cost

Waste of time? I dont think so.. Blow me :P

#3

Jeff,

Congrats the setup looks sweet cant wait to hear more stories on how it runs and some track times along with it.

You may compete with whitey's thread but you will never be the first

Congrats the setup looks sweet cant wait to hear more stories on how it runs and some track times along with it.

You may compete with whitey's thread but you will never be the first

#5

All I have to say is wow! That was a quick and awesome setup. Leave it to the creator of this site to build his own twin turbo setup  Is there a definate dyno day coming up soon?

Is there a definate dyno day coming up soon?

Is there a definate dyno day coming up soon?

Is there a definate dyno day coming up soon?

#9

Originally Posted by AbaZ

Shitty *** NAPA sold out of my favorite black hose I normally use and hand to use some homo *** red high pressure hose.

looks good... have fun blowing it up...

#10

I would also say this thing is pretty ------- fast, Jeff pulled jay pretty good on the freeway then Jay turned the boost up to 14-15 psi and Jeff pulled him a nice 2 car lengths. Great job on the setup Jeff, ill try to get Dave to make a vid with the footage I got.

steve

steve