building block, need suggestions

#41

actually that much machine work shouldnt cost that much

Blockwork

Deck,align hone ( if needed) ,then bore and hone cylinder to pistons shoudlnt cost more then $250

The crank ( you can send it to molodex they have nitriding avaiable) cut and nitride should be under $200. that included micro polishing the journals.

The rods wieght match with pistons ( yet again something a competent ) machine shop will do roughly $80

Balancing $150

Check rods and cleanup with honning if nessacary $80

thats about if. like i siad though. id at least studd the main caps. itll save your motor sometime down the road.

Blockwork

Deck,align hone ( if needed) ,then bore and hone cylinder to pistons shoudlnt cost more then $250

The crank ( you can send it to molodex they have nitriding avaiable) cut and nitride should be under $200. that included micro polishing the journals.

The rods wieght match with pistons ( yet again something a competent ) machine shop will do roughly $80

Balancing $150

Check rods and cleanup with honning if nessacary $80

thats about if. like i siad though. id at least studd the main caps. itll save your motor sometime down the road.

#42

Sean, you said not to post and get a blockgaurd? Why would anyone say that? You don't need to cut the crank or any of that ----, just get it micropolished. And honing the block with the head on, huh?

My whole motor is at the maching shop right now and it's not this complicated. There's no reason for half of the ---- you said unless you really fucked the motor the first time.

My whole motor is at the maching shop right now and it's not this complicated. There's no reason for half of the ---- you said unless you really fucked the motor the first time.

#46

I'm obviously not an engine "stud", but a local place to me called Midwest Machine builds pretty much everyones race engines for dirt oval track racing.. be it sprint, midget or stock car in my region. I know they dont have the heads on when boring. And if you know anything about Iowa you know its Sprint Car Capital

How would you avoid not wacking into the combustion chamber? Every boring bar I've seen have the retainer bolted on top which sticks up 1" or so above the boring tool and would total a combustion chamber!

I do know that when you get a block bored you must have the main caps with it, but thats a given to ensure proper alignment of the bores.

I think theres a big difference between realistic shade-tree mechanicing (like most of us here do) than building 12,000 RPM "spoon" engines.

How would you avoid not wacking into the combustion chamber? Every boring bar I've seen have the retainer bolted on top which sticks up 1" or so above the boring tool and would total a combustion chamber!

I do know that when you get a block bored you must have the main caps with it, but thats a given to ensure proper alignment of the bores.

I think theres a big difference between realistic shade-tree mechanicing (like most of us here do) than building 12,000 RPM "spoon" engines.

#47

ive had to Hone not Bore 3 a20a blocks with the head on becuase i dont have a Deck TQ plate. If i can get one made then ill stop doing it th wrong way. I have to bore them with the head off the right way. Depends on the style of hoen you use. theres a few that work this way.

your forgetting however that the d b h series engines. the cylinder head is part of the structure of the block. the head actually helps suppor thte main bearing saddles

Also posting is a big nonononononono itll lead to cylinder wall distrotion. Better to weld a deck plate in or leeve it alone. my advice. buy head studs and maind studs and say screw it with posting if you can't afford a weld in deck plate and all the maching nessacary.

As for the rest of the machine work i mentioned. It go to standardize and blue print the engine. I never trust anything that comes out of the box. Eagle arp carillo oliver etc. ive got improperly sized parts from evebody who makes them at one tiem or another.

The best way to build a good running engine is to standardize and properly machine everything. Your engine will run bette make mroe HP and last a lot longer if you take the proper steps.

If you need asitance in finding a capabel machine shop or need pricing drop me and emial and ill help you out. Id rather spend more mony on machine work then build an engine 2x

your forgetting however that the d b h series engines. the cylinder head is part of the structure of the block. the head actually helps suppor thte main bearing saddles

Also posting is a big nonononononono itll lead to cylinder wall distrotion. Better to weld a deck plate in or leeve it alone. my advice. buy head studs and maind studs and say screw it with posting if you can't afford a weld in deck plate and all the maching nessacary.

As for the rest of the machine work i mentioned. It go to standardize and blue print the engine. I never trust anything that comes out of the box. Eagle arp carillo oliver etc. ive got improperly sized parts from evebody who makes them at one tiem or another.

The best way to build a good running engine is to standardize and properly machine everything. Your engine will run bette make mroe HP and last a lot longer if you take the proper steps.

If you need asitance in finding a capabel machine shop or need pricing drop me and emial and ill help you out. Id rather spend more mony on machine work then build an engine 2x

#48

I would like to see one person that has had a sleeve distort because of a post up against it at 2 inch pounds.

A story found about Rob Smith from RPS:

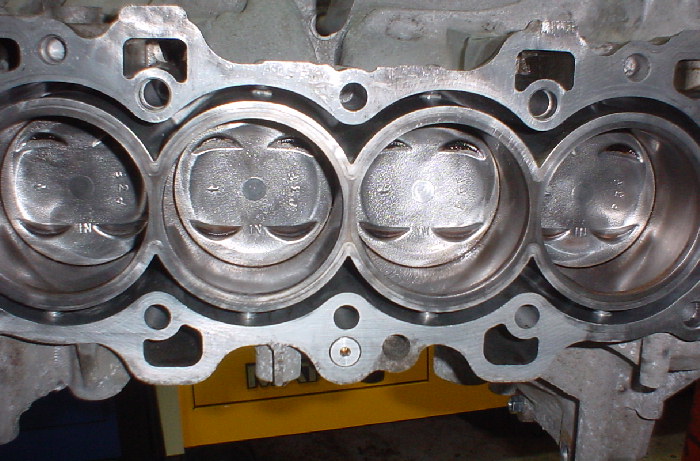

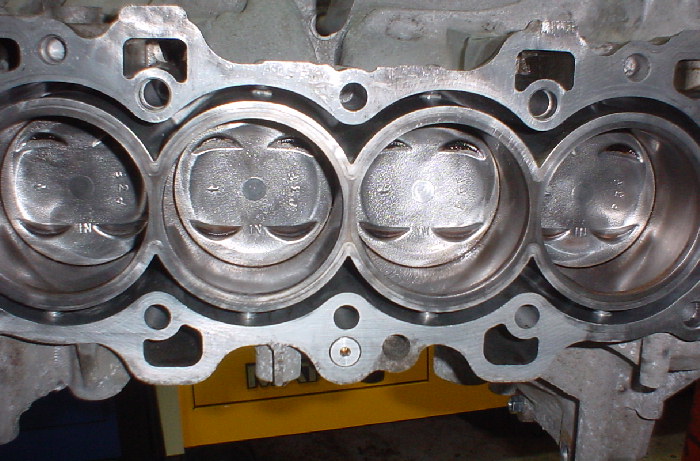

We asked Rob Smith over at RPS Turbo Clutch about using head plates when you have your cylinder bores honed. He's of the opinion that you don't need them on the late model Honda's because of their floating cylinder arrangement. You can see that the cylinders are siamesed together and they float in the water passage. When you torque on the head, any deflection or deformation caused by that force is not passed on to the cylinders. Instead, the block walls may flex and move into the water passage. The deformation is not carried to the cylinder bore to push it out of round.

A head plate is used on engines that have a deck surface to compensate for the deformation of the cylinder bore caused by the clamping force that holds the head onto the block. The deck surface distorts and causes the top of the cylinder bore to distort. A head plate mimics the distortion that occurs when the head is torqued to the block. When the cylinder bore is honed, it will be round when the real head is once again bolted on.

A story found about Rob Smith from RPS:

We asked Rob Smith over at RPS Turbo Clutch about using head plates when you have your cylinder bores honed. He's of the opinion that you don't need them on the late model Honda's because of their floating cylinder arrangement. You can see that the cylinders are siamesed together and they float in the water passage. When you torque on the head, any deflection or deformation caused by that force is not passed on to the cylinders. Instead, the block walls may flex and move into the water passage. The deformation is not carried to the cylinder bore to push it out of round.

A head plate is used on engines that have a deck surface to compensate for the deformation of the cylinder bore caused by the clamping force that holds the head onto the block. The deck surface distorts and causes the top of the cylinder bore to distort. A head plate mimics the distortion that occurs when the head is torqued to the block. When the cylinder bore is honed, it will be round when the real head is once again bolted on.

#49

Guest

Posts: n/a

that doesnt make much sense to me stealth...when you tighten down the head is it pushing on the cylinder walls as well....but i do agree about the posts not screwing anything up, and even if it did, a proper hone job would fix things just like it would after you welded in a block guard, which is sure to screw things up more initially (anyway, endyn stands by block posting, and i trust them)

#50

Basically what it says is that when you put a honda head onto the block, it doesn't align the cylinders with anything. The cylinders are floating, so say one is out of align, when you put the head on, what would pull that cylinder back into position? There isn't anything. The head is bolted to the block, but the cylinders are in the middle, and no bolt would pull them back where they should be. You would just have a head clamped onto the block, and the cylinder is not inline with the combustion chamber. Does that make more sense?

You have to think, if one of these was out of align, would it bring it back just by bolting the head on? Look at what actually gets the bolts.

You have to think, if one of these was out of align, would it bring it back just by bolting the head on? Look at what actually gets the bolts.