MIG welding 304 sch. 10, is "Stargon" OK to use?

#12

OK, I see how I get better penetration, but this leaves ---- hanging down inside the pipe. this will be a bitch to grind out inside the actual parts, no?

-The soldering station is being used to build a Megasquirt II v3.0 (fully loaded) -This project is entirely DIY...

gotta get to work for now, -any criticism on the last weld pics, will be gratefully appreciated

#13

I know its hard to do anything more than make 50 spot welds when you're starting out. That being said as soon as you ***** up and run a bead instead of ---- randomly hanging inside the weld you'll get a smooth bead running bearly on the inside of the pipe.

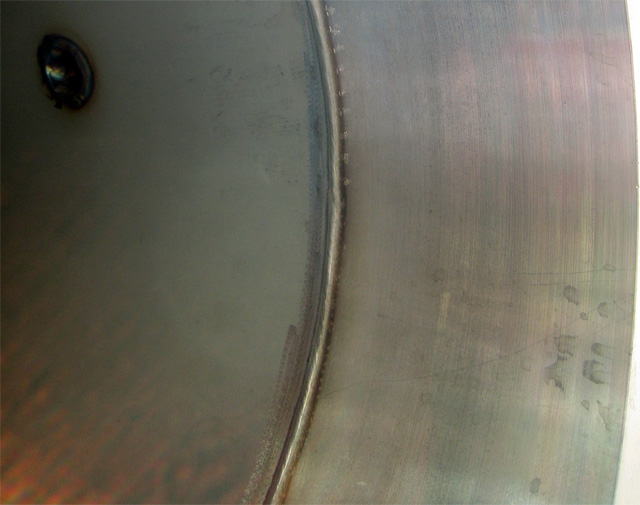

Like this but smaller.

or this

Instead of a bevel groove, that one is a J groove. (Take an angle grinder and just grind into it.) Good illustration of a landing too.

Middle bead on that (bearly visible) Now that is proper penitration for this size pipe. Whatever gap and landing that was, do it again and run a bead instead of a tack weld - even if it completely collapses out the backside no harm done. If you do one that does collapse out the backside - travel faster!

When you're welding slow processes like this one, as soon as the bead hits the width you want get moving & move fast/slow enough to maintain the width of the bead! Faster processes than this you just go LoL!

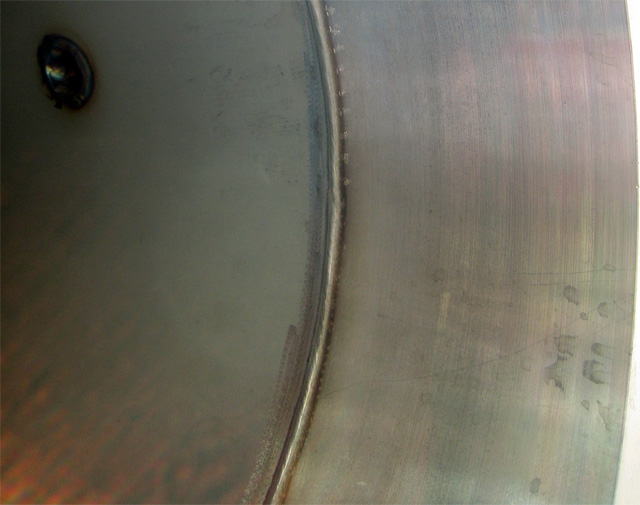

Like this but smaller.

or this

Instead of a bevel groove, that one is a J groove. (Take an angle grinder and just grind into it.) Good illustration of a landing too.

Middle bead on that (bearly visible) Now that is proper penitration for this size pipe. Whatever gap and landing that was, do it again and run a bead instead of a tack weld - even if it completely collapses out the backside no harm done. If you do one that does collapse out the backside - travel faster!

When you're welding slow processes like this one, as soon as the bead hits the width you want get moving & move fast/slow enough to maintain the width of the bead! Faster processes than this you just go LoL!

Thread

Thread Starter

Forum

Replies

Last Post

accordepicenter

Forced Induction

12

01-16-2004 09:54 AM