Manifold Fabrication

#1

I have been told to use 1 1/2 inch weld els for my manifold over and over but i cant believe it. That seems like too small a diameter to fit the ports of even my d series and i need to make a b series manifold.

so, what size are you guys using? maybe show me some pics if you could. especially the ports(looking into them if possible once again)

Thank you in advance you will be saving me money on returned orders of wrong parts from mcmaster!

peas out- tom

so, what size are you guys using? maybe show me some pics if you could. especially the ports(looking into them if possible once again)

Thank you in advance you will be saving me money on returned orders of wrong parts from mcmaster!

peas out- tom

#6

I was also wondering... i am going to use MIG because i have no access to a TIG machine at the time. what wire do you MIG guys use for the manifolds? do you use a 305 for the stainless to mild steel welds?

#7

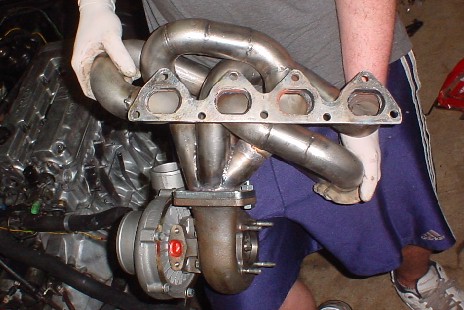

the welding el's are about 1.9 inches OD...actually the 1.5 OD tubes are slightly larger than the exhaust ports. You might want to grind the ports on the flange to get a smoother transition.

but go ahead and use the 1 1/2 ID elbows. (schedule 40) THEY WILL WORK.

thanks,

chris

but go ahead and use the 1 1/2 ID elbows. (schedule 40) THEY WILL WORK.

thanks,

chris

#8

i thank you sir. I am taking welding classes at my local vocational school and the instructor said that i will have to use a 305 MIG wire to wled the stainless to the mild steel. what do you guys use for MIG manifolds? i want stainless but i still need to work out all the details before i send my money to mcmaster.

thanks a ton -tom

thanks a ton -tom