Holset VGT HE351VE Controller

#81

I guess I have to? I dunno. I pulled the PIC out but forgot that the servo(yeah, the big expensive one) was plugged in. I wish I fried $5 chip instead of the $60 servo and wouldn't have happened if I wasn't so lazy and pulled a cheapy servo out of an RC car to test with. Big patch of black on the servo's PCB so I'm guessing it's toast. I'll try it again once I sort out my power supply. Still makes servo noises though.

I'll probably get more encouraged once I sell some cars and I have money again. but I'm starting to like your method too, a lot.

I'm leaning towards doing this instead of making a manifold. Turbo's too big to fit between head and strut tower on the two cars I am thinking of using it on. Works out a lot cheaper than making a manifold too. Do you guys think it'll make much of a difference between proper manifold and a manifold with bridge pipe on this vgturbo?

Do you guys think it'll make much of a difference between proper manifold and a manifold with bridge pipe on this vgturbo?

I'll probably get more encouraged once I sell some cars and I have money again. but I'm starting to like your method too, a lot.

I'm leaning towards doing this instead of making a manifold. Turbo's too big to fit between head and strut tower on the two cars I am thinking of using it on. Works out a lot cheaper than making a manifold too.

Do you guys think it'll make much of a difference between proper manifold and a manifold with bridge pipe on this vgturbo?

Do you guys think it'll make much of a difference between proper manifold and a manifold with bridge pipe on this vgturbo?

#82

What do you guys think of buying this and welding the turbo's oddball flange on to it? Since it is a spacer, it'll add block clearance at the same time as adding a wastegate.

#84

Apparently, the servo still works.

I had changed from a 16F84A(most basic chip around) to 16F88(chip with ADC's) and switched to the big servo and a new power supply. Went back to old power supply and didn't work so I changed chips and it now works. I'm gonna try using the 16F88 with a pin that's not connected to the ADC. Servo doesn't seem to show any signs of being broken either.

I had changed from a 16F84A(most basic chip around) to 16F88(chip with ADC's) and switched to the big servo and a new power supply. Went back to old power supply and didn't work so I changed chips and it now works. I'm gonna try using the 16F88 with a pin that's not connected to the ADC. Servo doesn't seem to show any signs of being broken either.

I would much rather buy that than fab. a manifold. and with me being pedantic, I would spend forever making a manifold and never get it done.

#85

I don't think the bends would affect the spool much as long as the interior of those welds were smooth. I would have some reservations on having a manifold that looks like a french horn though. There are so many welded joints in that, I'd be afraid the weight of the turbo would get the better of it, causing it to crack over time.

#86

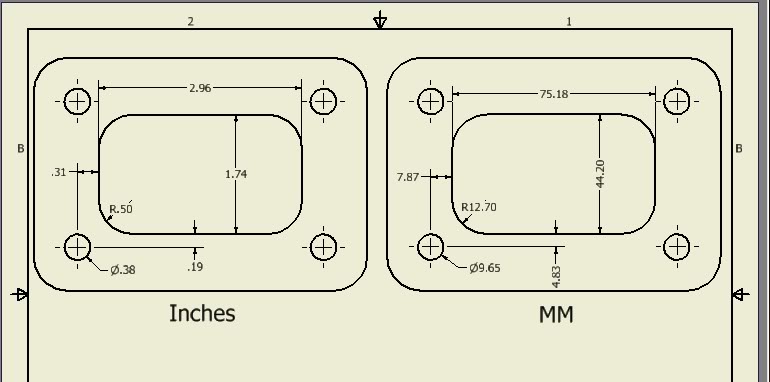

Ah screw it.. I'm just going to break down and make a manifold from scratch. I already have CAD drawings of both flanges and have access to a CNC plasma cutter and welder, so why not? I'm a little unsure if a well-built manifold can hold the weight of this turbo indefinitely without cracking. What do you guys think?

#87

Ah screw it.. I'm just going to break down and make a manifold from scratch. I already have CAD drawings of both flanges and have access to a CNC plasma cutter and welder, so why not? I'm a little unsure if a well-built manifold can hold the weight of this turbo indefinitely without cracking. What do you guys think?

#88

I'm not a native english speaker so I couldn't come up with beter words to describe my idea, hope it's easy to understand

Oh!!... and please remember that, just as turbo head flanges (well designed ones, that is) the holes must be oversize, bigger than the bolt diameter, otherwise you will defeat the purpose of the whole bracing thing and your manifold will crack even faster due to the extra stress caused by a very "dogged" brace.

Oh!!... and please remember that, just as turbo head flanges (well designed ones, that is) the holes must be oversize, bigger than the bolt diameter, otherwise you will defeat the purpose of the whole bracing thing and your manifold will crack even faster due to the extra stress caused by a very "dogged" brace.

Last edited by Turboedmav; 06-03-2010 at 02:24 AM.

#89

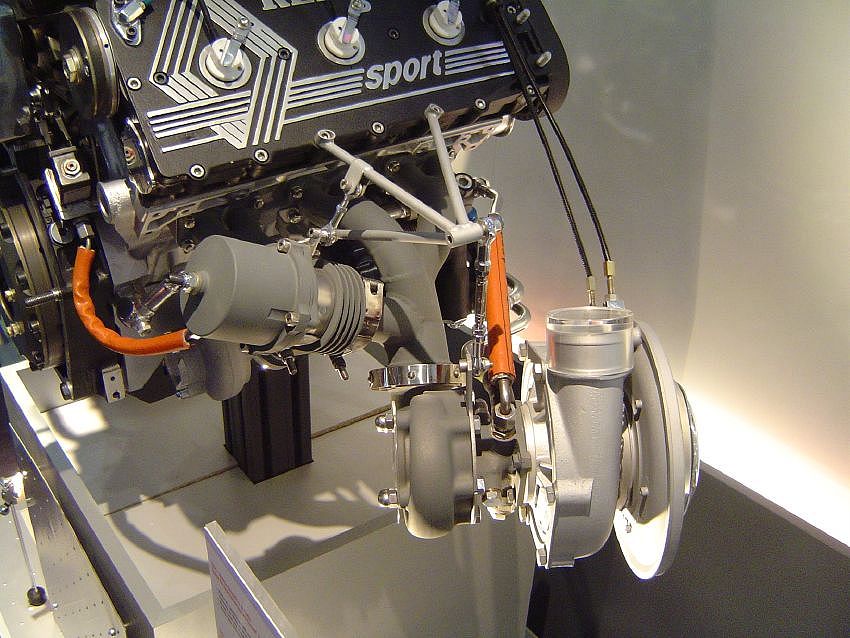

Turboedmav's words in pictures.

I wouldn't rely on manifold alone to hold my turbo up especially with the turbo way in front of the engine, like, next to the waterpump front. I want to make a manifold but it'll be too much downtime so I think I'll do what was done to the SR20 I posted earlier initially then make a mani. later.

What material? 304, 316, mild or even 321? Everyone in America seems to use 316, everyone here says use mild steel and ceramic coat. What thickness, sch 10/40, 14ga? I'm leaning towards mild in 12-14ga since strength at elevated temperatures is not a concern if the turbo is braced up like the pics?

#90

I like the first picture, where you can clearly see the flexible joints!... these braces are the fancy version of my "barebones" idea...  ... of course one can get as picky or as practical as one wishes... (I'll be making me a fancy one later on... all "blinged" up with shiny bits of stainless ... who said the ghetto approach can't look expensive? ...

... of course one can get as picky or as practical as one wishes... (I'll be making me a fancy one later on... all "blinged" up with shiny bits of stainless ... who said the ghetto approach can't look expensive? ...  Thanks for the pictures, saved me a lot of complicated explanations in case anyone asked for details...

Thanks for the pictures, saved me a lot of complicated explanations in case anyone asked for details...

... of course one can get as picky or as practical as one wishes... (I'll be making me a fancy one later on... all "blinged" up with shiny bits of stainless ... who said the ghetto approach can't look expensive? ...

... of course one can get as picky or as practical as one wishes... (I'll be making me a fancy one later on... all "blinged" up with shiny bits of stainless ... who said the ghetto approach can't look expensive? ...  Thanks for the pictures, saved me a lot of complicated explanations in case anyone asked for details...

Thanks for the pictures, saved me a lot of complicated explanations in case anyone asked for details...