Exhausted Opinions

#32

any change in diameter is a BAD thing. it causes turbulence.

intakes are tapered with velocity stacks because they are at a full vacuum at the inner end and atmos at the outer end.

you are right about cats (what are they? wtf, who has a cat :-p) and mufflers being key though.

stepping the exhaust part way along is a bad thing. if you had simply changed your mufflers, spool would havce increased, stepping up to 3" the whole way down would work better than the stepped system.

stepping up LOSES velocity in the same way that velocity stacks gain it in an intake.

besides which, the air coming from the turbine is rotating rather quickly and as such has a centrifugal force acting on it, and wants to escape outwards as well as backwards. going straight to your final diameter and not changing and not interfering with the flow is best.

your final diameter is length dependent too, just like wiring. if it had to go 6m instead of 3 you would need to upsize the exhaust

intakes are tapered with velocity stacks because they are at a full vacuum at the inner end and atmos at the outer end.

you are right about cats (what are they? wtf, who has a cat :-p) and mufflers being key though.

stepping the exhaust part way along is a bad thing. if you had simply changed your mufflers, spool would havce increased, stepping up to 3" the whole way down would work better than the stepped system.

stepping up LOSES velocity in the same way that velocity stacks gain it in an intake.

besides which, the air coming from the turbine is rotating rather quickly and as such has a centrifugal force acting on it, and wants to escape outwards as well as backwards. going straight to your final diameter and not changing and not interfering with the flow is best.

your final diameter is length dependent too, just like wiring. if it had to go 6m instead of 3 you would need to upsize the exhaust

#33

Originally Posted by fe3tcourier

stepping up LOSES velocity in the same way that velocity stacks gain it in an intake.

All I know is I'm happy with the end result. Now if I can figure out how to make my head flow like a honda....

#34

I have little respect for the man. a lot of what he says is outright wrong. i would however love to argue with him. at the least it would be entertaining watching him get frustrated.

one size pipe from end to end is best sized appropriately for acceptable pressure build up at peak power for the given length.

you define acceptable pressure build up.

one size pipe from end to end is best sized appropriately for acceptable pressure build up at peak power for the given length.

you define acceptable pressure build up.

#35

Originally Posted by fe3tcourier

I have little respect for the man. a lot of what he says is outright wrong. i would however love to argue with him. at the least it would be entertaining watching him get frustrated.

one size pipe from end to end is best sized appropriately for acceptable pressure build up at peak power for the given length.

you define acceptable pressure build up.

one size pipe from end to end is best sized appropriately for acceptable pressure build up at peak power for the given length.

you define acceptable pressure build up.

I respect him, but I don't think he's the final word and/or god, just to be clear.

I respect him, but I don't think he's the final word and/or god, just to be clear.The goal is flow; you want to keep the exhaust gases moving. A rapid decrease in temperature or rapid expansion and turbulence should cause the gases to slow. Starting with a matching port will keep the temps high and exhaust moving, as the exhaust cools the second it leaves the cylinder. This is also why we don't tend to port the exhaust on the head, but we do port the intake. Again, to keep the exhaust moving. It's really all a compromise. Throwing the 3" pipe on a 2" turbine outlet will cause both turbulence and a rapid decrease in EGTs, slowing the flow. But if you keep the exhaust moving out of the turbo with a matching port size the back pressure should drop more, since the area behind the turbo wants to keep moving rapidly into the stepped exhaust.

you may be right, i may be wrong. I don't see anything wrong with the idea. I'm no engineer or expert, but I do know the difference from my 2.25" to my 3" catback was substantial.

#36

trouble is, the air exiting the turbo is extremely non laminar in the first place. once the turbulence and twisting settles down the pipe a little bit, thats where you need to care that its dead smooth to the end. the only thing the turbine cares about is having a low pressure zone to dump to. the exhaust is expanding as it goes through the turbine, that is what makes it work. the more freely it can expand as it exits, the better. a dump out the side 6" wide would be nice, but kinda loud. its impossible to get better than that. velocity in exhaust systems is used for scavenging usually. there is only scavenging before the turbo because of the pressure pulses and runner arrangement.

as for porting intakes, intakes are the path that is under suction. when under suction, the restriction causes a larger pressure drop to the end and you get less air in. when under pressure with a piston pushing the gas out, the exhaust can be pretty crap and will still work ok. its forced to leave regardless of how nasty the engine is. improving things there reduces pumping losses (power required to push ex out) and heat because the overall pressure in the exhaust track is on the average, lower.

disclaimer : very tired and very pissed off right now, if i muddled something, dont jump on me too hard. should be pretty on the money though.

as for porting intakes, intakes are the path that is under suction. when under suction, the restriction causes a larger pressure drop to the end and you get less air in. when under pressure with a piston pushing the gas out, the exhaust can be pretty crap and will still work ok. its forced to leave regardless of how nasty the engine is. improving things there reduces pumping losses (power required to push ex out) and heat because the overall pressure in the exhaust track is on the average, lower.

disclaimer : very tired and very pissed off right now, if i muddled something, dont jump on me too hard. should be pretty on the money though.

#37

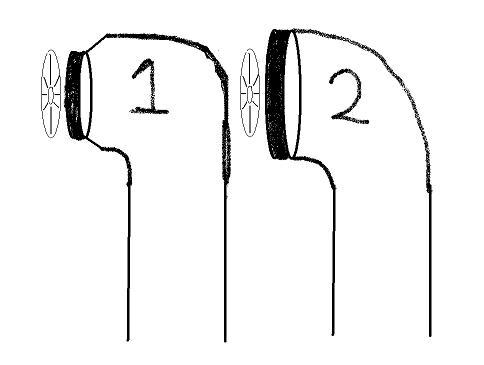

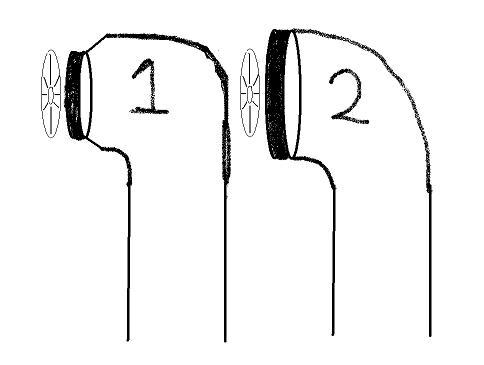

ok time for some ms paint

would there be a big difference in the flow of these 2 down pipes

the turbine is from a 16g (not sure on diameter) and the dp is 2.5''

i already have the flange for #2 so id have to get another one and a step up pipe, i also think id have to make the 90 bend down a bit sharper for space

would there be a big difference in the flow of these 2 down pipes

the turbine is from a 16g (not sure on diameter) and the dp is 2.5''

i already have the flange for #2 so id have to get another one and a step up pipe, i also think id have to make the 90 bend down a bit sharper for space

#38

if the distance is as you say, the difference would be negligible. i personally went for number 2 on mine (hy35 dumping into straight 4 inch and then tapering down to 3 inch over 300mm because 4" muffler parts come from trucks) i would have preferred to use a 3" straight off the exducer, and just use the 4" flange for mounting, but it was easier this way. i certainly would have gone to the trouble of tapering up from the turbine to the pipe.

up to you. we are splitting hairs.

i just wanted to point out that the stepping the exhaust part way down wasnt ideal. thats all.

up to you. we are splitting hairs.

i just wanted to point out that the stepping the exhaust part way down wasnt ideal. thats all.

#39

I'm not really arguing, it's the only way, when I started talking to Corky, I was really taught. With that said, here's a pic of mine.

2.5" to mathc my turbine, and 2.75" after the swag joint.

3" at the testpipe.

either way will work, without back to back testing, its hard to say which one is best, the difference could easily be none. I'll comprmise and say as long as you do 2.5" mandrel you should be good. how 'bout that?

2.5" to mathc my turbine, and 2.75" after the swag joint.

3" at the testpipe.

either way will work, without back to back testing, its hard to say which one is best, the difference could easily be none. I'll comprmise and say as long as you do 2.5" mandrel you should be good. how 'bout that?