welded engine mounts... still need a flex section?

#11

im just thinking that if the engine even twists the mounts a little bit on a hard launch, that little bit of movement can put alot of leverage on the exaust manifold if the entire exaust doesnt move with it, youre better off so it wont crack or anything in the long run

#13

1- im not a noob~

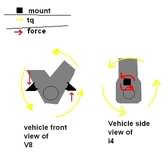

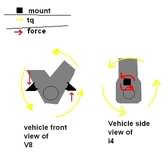

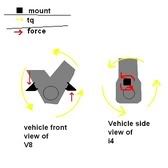

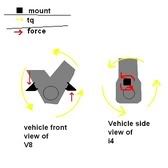

2- in a FWD car, the forces of engine torque are leveraged on the motor mounts in a twisting fashion, where as in a RWD car, they would be pressure and lifting force... Heres a quick drawing..

Personnally, i wouldnt weld my motor mounts IMO. (fwd honda)

but if you are, deffinately get a flex section. Remember your hangers will give a little bit too.

2- in a FWD car, the forces of engine torque are leveraged on the motor mounts in a twisting fashion, where as in a RWD car, they would be pressure and lifting force... Heres a quick drawing..

Personnally, i wouldnt weld my motor mounts IMO. (fwd honda)

but if you are, deffinately get a flex section. Remember your hangers will give a little bit too.

#14

Im still going to weld them, because when I start feeding 200+ HP through a tranny designed to hold 88, Its going to need all the help it can get to survive... The escort tranny sucks to begin with, let along when you start hammering the ---- out of it. Im also going to get a flex section as well.

#15

Originally Posted by IowaTCoupe

1- im not a noob~

2- in a FWD car, the forces of engine torque are leveraged on the motor mounts in a twisting fashion, where as in a RWD car, they would be pressure and lifting force... Heres a quick drawing..

Personnally, i wouldnt weld my motor mounts IMO. (fwd honda)

but if you are, deffinately get a flex section. Remember your hangers will give a little bit too.

2- in a FWD car, the forces of engine torque are leveraged on the motor mounts in a twisting fashion, where as in a RWD car, they would be pressure and lifting force... Heres a quick drawing..

Personnally, i wouldnt weld my motor mounts IMO. (fwd honda)

but if you are, deffinately get a flex section. Remember your hangers will give a little bit too.

they twist just like you drew.

they twist just like you drew.

#17

I've seen a lot of Pro FWD cars that use solid mounts. They don't break. If this is for a daily driver, I would refrain from having solid mounts. The vibration would get annoying after awhile. You should just fill them with urethane.

#19

Originally Posted by bmaca455

who would have thought that pressure upwards on one side of something and downwords on the other side would create lift??!! :1

BUt ya man, go ahead. vibratin is fun, have ur girl hold ur shifter... an watch her bite her lip an close her eyes~ j/k man

#20

unibody cars made from sheet metal and solid engine mounts dont last,most V8 cars have real frames or at least subframes. Get a welder so you can mig up the cracks, I love people that look at race cars for there street car ideas