Spoolin performance welding update

#31

Originally Posted by Engloid

Is that a one pass "full race" style weld?

It's really hard to get consistent penetration doing it that way.

It's really hard to get consistent penetration doing it that way.

"full race"

explain.

explain.

#32

Orbital pipe welders can feed however much wire they need at any rate needed. Your hand can not do indefinately.

Youll find more .065 .052 and .045 automated tig welders than you will .023. When you buy in bulk, the thicker the wire the cheaper. The smaller the wire, the more times it has to be drawn through the die hickey that sizes it. Larger wire is less wear on the feed too.

The few automated tigs Ive run across are all hot-wire anyway. They pre-heat the wire Im guessing 350-600*F before it hits the puddle.

Define what you call a full pen weld. Show me an example picture (doesn't matter who's, or on what).

Youll find more .065 .052 and .045 automated tig welders than you will .023. When you buy in bulk, the thicker the wire the cheaper. The smaller the wire, the more times it has to be drawn through the die hickey that sizes it. Larger wire is less wear on the feed too.

The few automated tigs Ive run across are all hot-wire anyway. They pre-heat the wire Im guessing 350-600*F before it hits the puddle.

Define what you call a full pen weld. Show me an example picture (doesn't matter who's, or on what).

#33

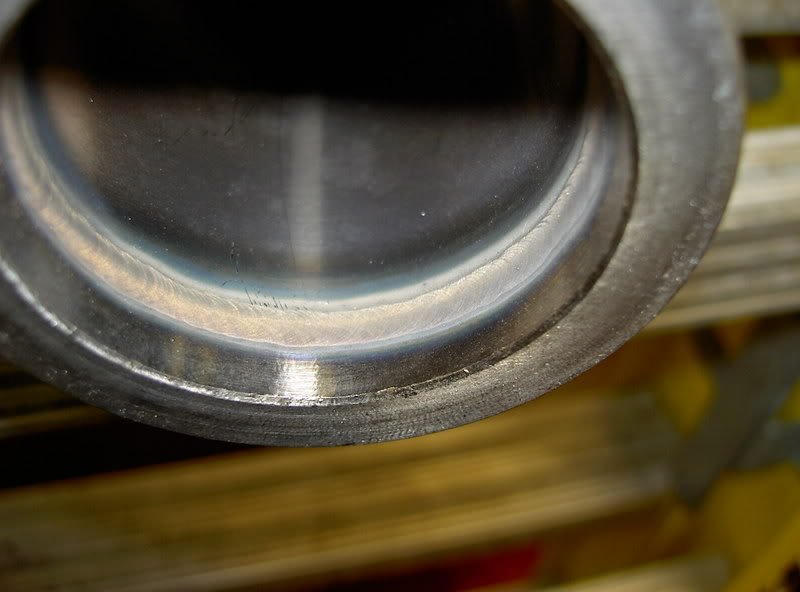

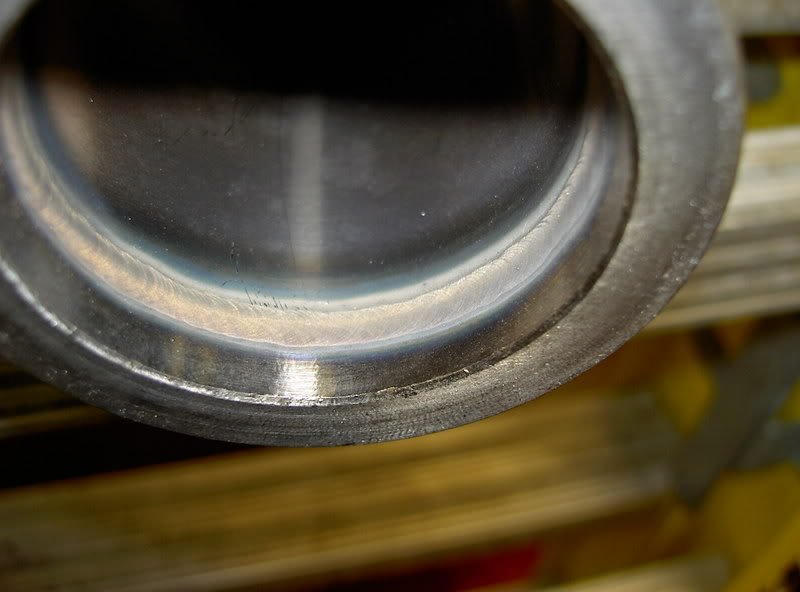

Here's some sanitary grade 304 ss, .065" wall, 2" tube. I made this weld in the 5g position(no positioner or turn rolls), and without amperage control.

That was from 2 years ago, I used a maxstar150stl, scratch start baby

I have gotten better now, I can make 5g and 6g position welds with my dynasty machines a lot smaller, I'll try and get some pics tomorrow.

That was from 2 years ago, I used a maxstar150stl, scratch start baby

I have gotten better now, I can make 5g and 6g position welds with my dynasty machines a lot smaller, I'll try and get some pics tomorrow.

#36

Originally Posted by Toysrme

Orbital pipe welders can feed however much wire they need at any rate needed. Your hand can not do indefinately.

Youll find more .065 .052 and .045 automated tig welders than you will .023. When you buy in bulk, the thicker the wire the cheaper. The smaller the wire, the more times it has to be drawn through the die hickey that sizes it. Larger wire is less wear on the feed too.

The few automated tigs Ive run across are all hot-wire anyway. They pre-heat the wire Im guessing 350-600*F before it hits the puddle.

Define what you call a full pen weld. Show me an example picture (doesn't matter who's, or on what).

Youll find more .065 .052 and .045 automated tig welders than you will .023. When you buy in bulk, the thicker the wire the cheaper. The smaller the wire, the more times it has to be drawn through the die hickey that sizes it. Larger wire is less wear on the feed too.

The few automated tigs Ive run across are all hot-wire anyway. They pre-heat the wire Im guessing 350-600*F before it hits the puddle.

Define what you call a full pen weld. Show me an example picture (doesn't matter who's, or on what).

The thing I think you are missing is that for .065" material you shouldn't be adding much filler at all, if you want a high deposition rate weld, its best to use GMAW.

#37

How we got on orbital machines?

I *think* it's because Engloid nuked Full-Race LONG ago for being the first startup manifold biz on the net with an "automated tig welder" machine back in the day (AKA mexican kid down the street pushing a button). They were welding so uncontrollably hot with it trying to do single passes they had to start & stop ungodly often. When I mean often, I mean Beyond what you see most smart newbies start and stop. Stuff looked on the verge of burning up. Had they not been wire-brushing some of the welds you could see the luster was gone. Inconsistant pen without burning it up or nuking the grain struture in the HAZ in some way - Which is what Passenger is trying to state. Yes, it requires alittle more skill to do... LoL!

Basically after FR was saying all this bullshit about how great their machines and operators, engineers, programmers, blah blah blah were their welds would have tanked out under your normal pipe / pressure vessle codes.

Passenger, you're right on the ### rate. That's why alot of automated systems now use hot-wire. Same reason for people using the super high pulse rates in manual/automated tig now. Up that ### rate to up that work rate & save $ buying wire. Haven't seen a fast pulse hot-wire yet, but Im sure someone has put the two together. Id really like to see that on some major production machine.

My point was that if you're ontop of it. You shouldn't have a problem with burning it up, having a gigantic bulky weld or a grain structure problem in the HAZ.

Orbital pipe welders? Na, Ive seen more orbital welders than Ive used. Seen more sit idle than Ive seen in use too. The places Ive been too only use the orbital welders so they can have some newbie run it - which doesn't work out because there's always some GD problem that the $9/h loader/button masher can't deal with. Then they have to retain some smart guy who gets paid more because he knows how to program the stupid things - who takes his ------- time getting to the machine let alone fixing the GD thing. Winds up having so much down-time it's just cheaper to pay a real welder and have him work extra. LoL! Ive done alittle bit with an orbital welder. Didn't like it much. Seemed to take all god damned day to fix mechanical issues then program it to do whatever new weld its doing. Wasn't god's gift to orbital welders. Some old POS. Im sure a newer less worn out one would be puffy nipples.

Weld looks good. I was expecting more what afew people on here consider a weld with some pen. I.E. there are heatmarks on the backside and nothing is broken down LoL! Just inconsistant and alot of suckback when there is any pen from trying to move too fast with too small a root opening. Great to see a nice even breakdown on the backside. What was the backside reinforcement on that? Normally when I get down to doing tube alot of times some small amount of backside reinforcement is still asked for. I see 1/32-1/16 alot.

Soooo many codes. Don't quote me on ASME. I haven't sat down and read any of it in along while, but I *think* for single welded but joints the maximum inner and outer reinforcement though 1/8" thickness is 3/32". 1/8" - 3/16" thickness it's 3/32" inner and 1/8" outer. Sometimes you don't even need an inner tho. At 700-800*F you want 1/16" reinforcement. Not sure don't own an ASME code book.

I *think* it's because Engloid nuked Full-Race LONG ago for being the first startup manifold biz on the net with an "automated tig welder" machine back in the day (AKA mexican kid down the street pushing a button). They were welding so uncontrollably hot with it trying to do single passes they had to start & stop ungodly often. When I mean often, I mean Beyond what you see most smart newbies start and stop. Stuff looked on the verge of burning up. Had they not been wire-brushing some of the welds you could see the luster was gone. Inconsistant pen without burning it up or nuking the grain struture in the HAZ in some way - Which is what Passenger is trying to state. Yes, it requires alittle more skill to do... LoL!

Basically after FR was saying all this bullshit about how great their machines and operators, engineers, programmers, blah blah blah were their welds would have tanked out under your normal pipe / pressure vessle codes.

Passenger, you're right on the ### rate. That's why alot of automated systems now use hot-wire. Same reason for people using the super high pulse rates in manual/automated tig now. Up that ### rate to up that work rate & save $ buying wire. Haven't seen a fast pulse hot-wire yet, but Im sure someone has put the two together. Id really like to see that on some major production machine.

My point was that if you're ontop of it. You shouldn't have a problem with burning it up, having a gigantic bulky weld or a grain structure problem in the HAZ.

Orbital pipe welders? Na, Ive seen more orbital welders than Ive used. Seen more sit idle than Ive seen in use too. The places Ive been too only use the orbital welders so they can have some newbie run it - which doesn't work out because there's always some GD problem that the $9/h loader/button masher can't deal with. Then they have to retain some smart guy who gets paid more because he knows how to program the stupid things - who takes his ------- time getting to the machine let alone fixing the GD thing. Winds up having so much down-time it's just cheaper to pay a real welder and have him work extra. LoL! Ive done alittle bit with an orbital welder. Didn't like it much. Seemed to take all god damned day to fix mechanical issues then program it to do whatever new weld its doing. Wasn't god's gift to orbital welders. Some old POS. Im sure a newer less worn out one would be puffy nipples.

Weld looks good. I was expecting more what afew people on here consider a weld with some pen. I.E. there are heatmarks on the backside and nothing is broken down LoL! Just inconsistant and alot of suckback when there is any pen from trying to move too fast with too small a root opening. Great to see a nice even breakdown on the backside. What was the backside reinforcement on that? Normally when I get down to doing tube alot of times some small amount of backside reinforcement is still asked for. I see 1/32-1/16 alot.

Soooo many codes. Don't quote me on ASME. I haven't sat down and read any of it in along while, but I *think* for single welded but joints the maximum inner and outer reinforcement though 1/8" thickness is 3/32". 1/8" - 3/16" thickness it's 3/32" inner and 1/8" outer. Sometimes you don't even need an inner tho. At 700-800*F you want 1/16" reinforcement. Not sure don't own an ASME code book.

#38

The high pulse rates, like 400+ pps are used to agitate the puddle, it gives the arc some stability especially in a 5g position weld, which is exactly what an orbital machine has to deal with. When you are using a stationary head and a positioner or turn rolls to rotate the workpiece you can better weld quality and repeatability. Hopefully in a few weeks I'll be done the first phase of my automated tig machine, I'll be sure to post up some results, for now it will be cold wire, but maybe I'll come up with a hot wire system in the future. I honestly don't really have any experience with hotwire systems, I've never programed one, but its something I'd like to get some experience with.

Orbital welders really are kind of lame, they are so limited in what they can do, and really, you need a skilled operator on them half the time anyways to adjust the programs for different parts etc, he may as well just weld them by hand. Orbital machines are only useful if you are making thousands of the same part. I get called in to program them, but usually end up having to convince the owner that they got shafted on the purchase, the sales guys make it sound like any nog can just program it and than its good for the rest of its service life but it isn't just that simple.

By reinforcement you mean weld protrusion depth on the I.D. right? Or are you talking Width?

Depth we shoot for .010"-.035", width no less than .065-.095", .100" is great, going much less we found brings stress risers in weld wetting area which led to pressure holding issues. Automated you can go bit thinner.

Orbital welders really are kind of lame, they are so limited in what they can do, and really, you need a skilled operator on them half the time anyways to adjust the programs for different parts etc, he may as well just weld them by hand. Orbital machines are only useful if you are making thousands of the same part. I get called in to program them, but usually end up having to convince the owner that they got shafted on the purchase, the sales guys make it sound like any nog can just program it and than its good for the rest of its service life but it isn't just that simple.

By reinforcement you mean weld protrusion depth on the I.D. right? Or are you talking Width?

Depth we shoot for .010"-.035", width no less than .065-.095", .100" is great, going much less we found brings stress risers in weld wetting area which led to pressure holding issues. Automated you can go bit thinner.

#39

DIY automated welder hell mother ------- yes. Been wanting to make something like a CNC router for years. (CNCZone).

Hotwire is nice, increases work rate and decreases shock in the weld puddle when the wire is put in.

Im not a big fan of automated welders. It seems like you never find anyone that has a mint condition one that's 100%, then once it's programmed to actually do something useful in spec. Someone comes along and jacks the ------- work rate on it until it near maxes itself out. Ya well, afew months later it runs like a piece of ----. The programming has been adjusted so many times it needs to be reprogrammed from scratch. Downtown is ungodly unacceptable yet noone will take the time while it is down to run in there and start from scratch.

We took a class on a generic ABB robot. Pretty new. Good condition. I worked at a place with six identical models. Most of them wouldn't out-produce a single $9/h manual welder because of how they wore them out. When I got into a position I could do it I had the tool crib boss order once full set of replacement needle roller bearings, shims & a brand new wrist. Had those installed on the worst robot. Reprogrammed it from scratch & SLOWED IT DOWN.

What it lost in flat out speed it made up for by being able to run most of the day without problems.

They're all cool and all when they're new and great condition. Noone really trying to push one to it's full ability. Really, they're stupid. They can't correct their own problems.

The height and width.

Hotwire is nice, increases work rate and decreases shock in the weld puddle when the wire is put in.

Im not a big fan of automated welders. It seems like you never find anyone that has a mint condition one that's 100%, then once it's programmed to actually do something useful in spec. Someone comes along and jacks the ------- work rate on it until it near maxes itself out. Ya well, afew months later it runs like a piece of ----. The programming has been adjusted so many times it needs to be reprogrammed from scratch. Downtown is ungodly unacceptable yet noone will take the time while it is down to run in there and start from scratch.

We took a class on a generic ABB robot. Pretty new. Good condition. I worked at a place with six identical models. Most of them wouldn't out-produce a single $9/h manual welder because of how they wore them out. When I got into a position I could do it I had the tool crib boss order once full set of replacement needle roller bearings, shims & a brand new wrist. Had those installed on the worst robot. Reprogrammed it from scratch & SLOWED IT DOWN.

What it lost in flat out speed it made up for by being able to run most of the day without problems.

They're all cool and all when they're new and great condition. Noone really trying to push one to it's full ability. Really, they're stupid. They can't correct their own problems.

The height and width.

#40

Yeah I am pretty stoked I am finally getting it all together, I have been planning and dreaming of building an automated tig machine for the last 3 or 4 years, its just finally coming into play now. It'll be cool cause than I can seem weld or turning work as well

For now I am just going to power all the axis so its more like a semi automatic setup, but when I get time and money I want to make it fullyl automated (need to find that kind of work first).

For now I am just going to power all the axis so its more like a semi automatic setup, but when I get time and money I want to make it fullyl automated (need to find that kind of work first).