beaded ends on the pressure pipe? How Important?

#11

basically for the vice grips you build up weld on one fo the sets of teeth, and than grid it to a point than you grind out the other set of teeth to accept the teeth with the point.....easy....

#15

ok, I did a test bend on one of my scrap pieces. this it what I came up with:

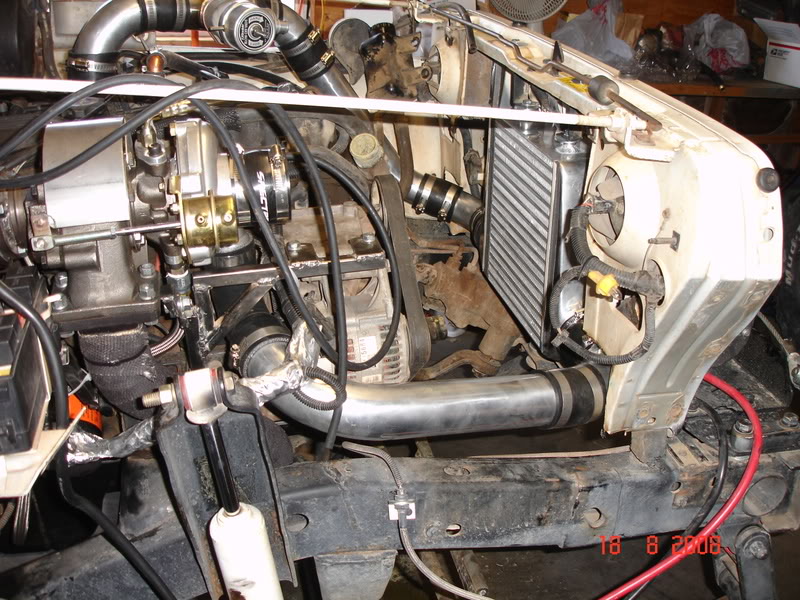

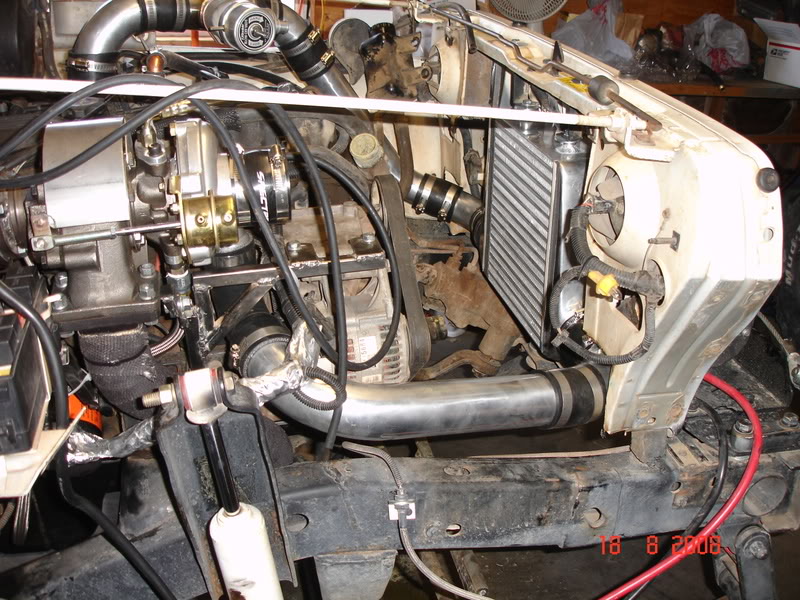

and here is a pic of where I am at:

I am going with the first pic of what i will do to my charge pipes

thank you for the insight.

and here is a pic of where I am at:

I am going with the first pic of what i will do to my charge pipes

thank you for the insight.

#17

That looks like your going to need a 6 inch long coupler to even seal on that pipe.

I would never consider having something like that, and expecting it to seal. I would just leave them be. I was running 11psi with non beaded pipe, and worm clamps, and I never blew a pipe off.

I would never consider having something like that, and expecting it to seal. I would just leave them be. I was running 11psi with non beaded pipe, and worm clamps, and I never blew a pipe off.

#19

Originally Posted by mopar318

That looks like your going to need a 6 inch long coupler to even seal on that pipe.

I would never consider having something like that, and expecting it to seal. I would just leave them be. I was running 11psi with non beaded pipe, and worm clamps, and I never blew a pipe off.

I would never consider having something like that, and expecting it to seal. I would just leave them be. I was running 11psi with non beaded pipe, and worm clamps, and I never blew a pipe off.

I do have T-bolt clamps on order. Whats the worst that can happen? I blow a pipe, then I limp home and do something about it. No big deal. This Jeep is not my DD. Its a pure toy. So I can thrash on it without any worries or cares.

And Bigdaddyvtec,

thanks for looking. Us rockcrawlers like some power as well you know. And don't be surprised if you see that jeep on the street busting up some of the poser DSM's I see here in Barstow!!

#20

Originally Posted by jagojon3

If you have any problems fitting your coupler over that just lube it up with some dish soap.