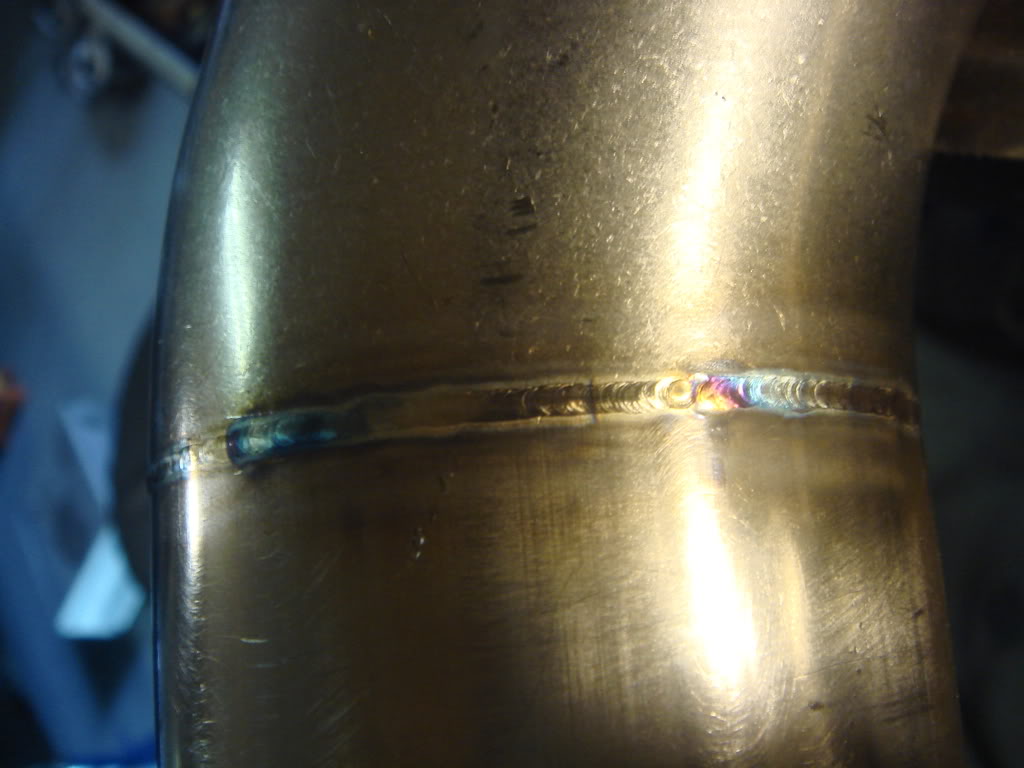

16 gauge manifold pics

#22

Originally Posted by Passenger

|Whoa your welds are really wide man, what kind of shape you got on your tungsten?

I could probably get them a bit smaller, but the bigger puddle I seem to get more consistent pen. I need more practice, as usual.

#24

Thanks man! I really appreciate having insight from someone who does it every day.

I feel like I am really a student of welding and really want to know how do do it right, so advice from more experienced guys is gold.

I will try grinding a land on- I remember hearing to do that but I'd also heard they should be needle sharp. But really, it only stays that way for about 10 seconds anyways. Any other thoughts on the "wide beads"? Is it inherently bad?

The welds on the runners are narrower than the collector- right at 5/32" wide which seems to look fairly "proportional" for 1/16" material. Those collector welds are pushing 1/4"thoiugh which doesn't seem right, or at least not necessary. I think I was being paranoid about getting full-pen and used more heat than necessary (they just didn't turn grey because the shielding was good I suppose).

I suspect I should experiment with what sort of puddle size I actually need for full pen, rather than go overkill.

Last thing - any thoughts on weld bead reinforcement? I see headers with beads that are pretty much flush to the outside- I have always heard that especially on thinner material you always want some reinforcement top and bottom- obviously though the less convex you make the bead, the easier it is to make a nice weld and not lose puddle control.

The other theory I have heard is that the weak spot will always be the haz, and as long as the weld is minimum the thickness of the material (like, flush on the outside, with a bit of inside reinforcement just due to the puddle sinking a bit) there's no point in adding more material to the top of the weld, since you aren't strengthening the weakest point.

Any thoughts?

Thanks again!

I feel like I am really a student of welding and really want to know how do do it right, so advice from more experienced guys is gold.

I will try grinding a land on- I remember hearing to do that but I'd also heard they should be needle sharp. But really, it only stays that way for about 10 seconds anyways. Any other thoughts on the "wide beads"? Is it inherently bad?

The welds on the runners are narrower than the collector- right at 5/32" wide which seems to look fairly "proportional" for 1/16" material. Those collector welds are pushing 1/4"thoiugh which doesn't seem right, or at least not necessary. I think I was being paranoid about getting full-pen and used more heat than necessary (they just didn't turn grey because the shielding was good I suppose).

I suspect I should experiment with what sort of puddle size I actually need for full pen, rather than go overkill.

Last thing - any thoughts on weld bead reinforcement? I see headers with beads that are pretty much flush to the outside- I have always heard that especially on thinner material you always want some reinforcement top and bottom- obviously though the less convex you make the bead, the easier it is to make a nice weld and not lose puddle control.

The other theory I have heard is that the weak spot will always be the haz, and as long as the weld is minimum the thickness of the material (like, flush on the outside, with a bit of inside reinforcement just due to the puddle sinking a bit) there's no point in adding more material to the top of the weld, since you aren't strengthening the weakest point.

Any thoughts?

Thanks again!

#25

Keep your exterior width to around 1/8" or less. Practice on some scrap and see what you can come up with, high speed pulse will help tighten up the puddle, especially in difficult positions. The biggest thing is practice, keep your torch moving as smoothly as possible. Having a landing on your tungsten is going to give you better penetration, so does less taper on the grind, but as a trade off you lose arc stability. With a fine tip like you have you will have great arc control, but shallow penetration and if your current is the same you will just get a wide bead.

#28

a little late but, the throat of the weld should be equal to the thicnkess of the smallest piece of base metal. (and in some places concave, but the size of those spots correctly goes up to compensate the thinning throat size)

so for your T joints unlike soooo many others you are actually producing the correct size convex weld profile on them.

reinforcement should add to no more than 1/8". on this smaller pipe just a smidge on the inside & outside are what you typically shoot for.

for the tips the angle on it is fine. you want them to be trunctuated. just touch the tip to whatever you are grinding it with to get a flat spot. the point to doing so is that it gives the arc a set place to jump off from compaired to ringing its way around a point from which ever side of the point is closest to the base metal.

the pen looked really good in some spots!

so for your T joints unlike soooo many others you are actually producing the correct size convex weld profile on them.

reinforcement should add to no more than 1/8". on this smaller pipe just a smidge on the inside & outside are what you typically shoot for.

for the tips the angle on it is fine. you want them to be trunctuated. just touch the tip to whatever you are grinding it with to get a flat spot. the point to doing so is that it gives the arc a set place to jump off from compaired to ringing its way around a point from which ever side of the point is closest to the base metal.

the pen looked really good in some spots!