Kevin's Compound Sequential Twin Turbo Design

#1

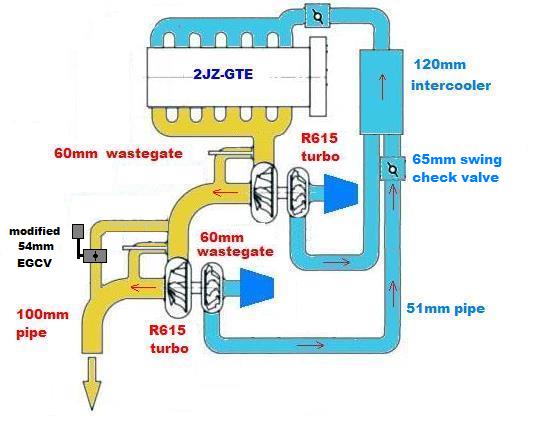

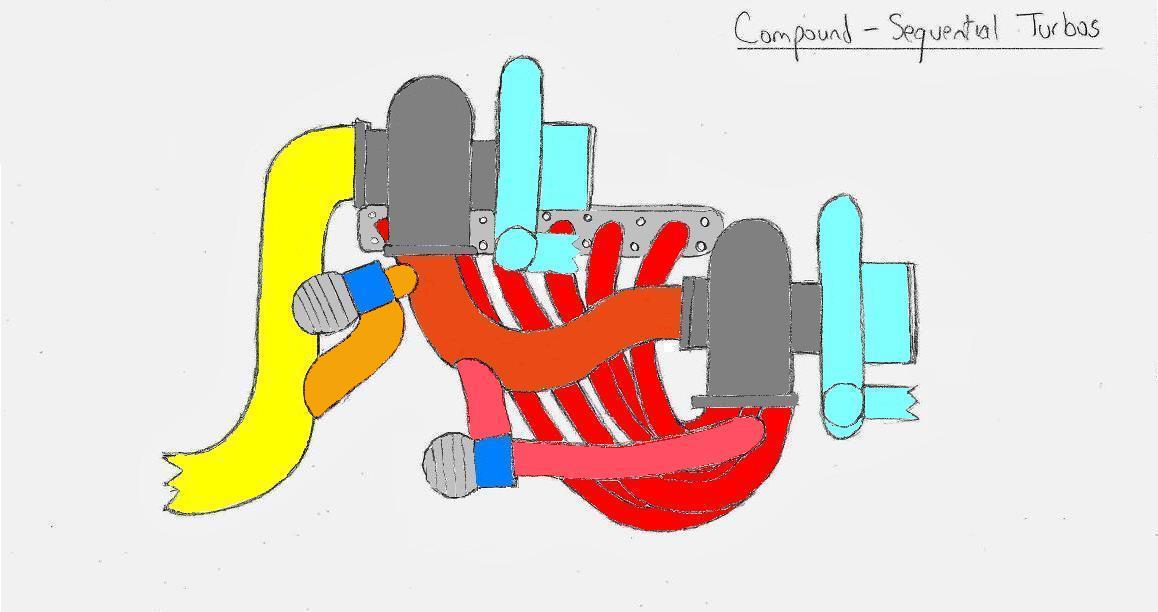

They say a picture is worth a thousand words, so here's a diagram of how it works.

This sequential setup is basically a compound turbo setup on the exhaust side (but with identical size turbos) and a sequential setup on the intake side. This means you get all the advantages of a compound turbo setup for spooling the turbos, but with none of the disadvantages of the compound setup such as the boost being too high for a gas engine. Also both turbos are exactly the same size, so you don't get any issues with different size turbos fighting each other in the sequential setup and having the large one potentially overpowering the smaller one.

By spooling the second turbo with the gas exiting from the first turbo, the second turbo will spool much quicker then if it was just receiving some exhaust gas diverted from the first turbo, as most other sequential turbo systems do. This means that instead of having a big dip in the torque curve when the second turbo comes on-line, there should be little to no dip in the torque, resulting in a torque curve more like a large single turbo.

This setup is super simple and only requires 2 devices to be controlled, which is simpler then any other sequential turbo setup I've seen. There are two wastegates, one used for each turbo and they are set to exactly the same boost level. These wastegates need to be controlled separately as the two turbos will require different duty cycles on the wastegate to maintain the same boost level. This can be done with one aftermarket ECU as long as it has free outputs.

The factory 2JZ-GTE Exhaust Gas Control Valve (EGCV) is modified so that it is open when the actuator is not activated. This is so the #1 turbo has reduced back pressure so that it can spool faster. When the boost from the #1 turbo reaches 7psi, the actuator automatically closes and this allows the #2 turbo to start spooling.

The swing check valve (SCV) is used as a one way valve so that the boost pressure from the #1 turbo does not feed back through the #2 turbo.

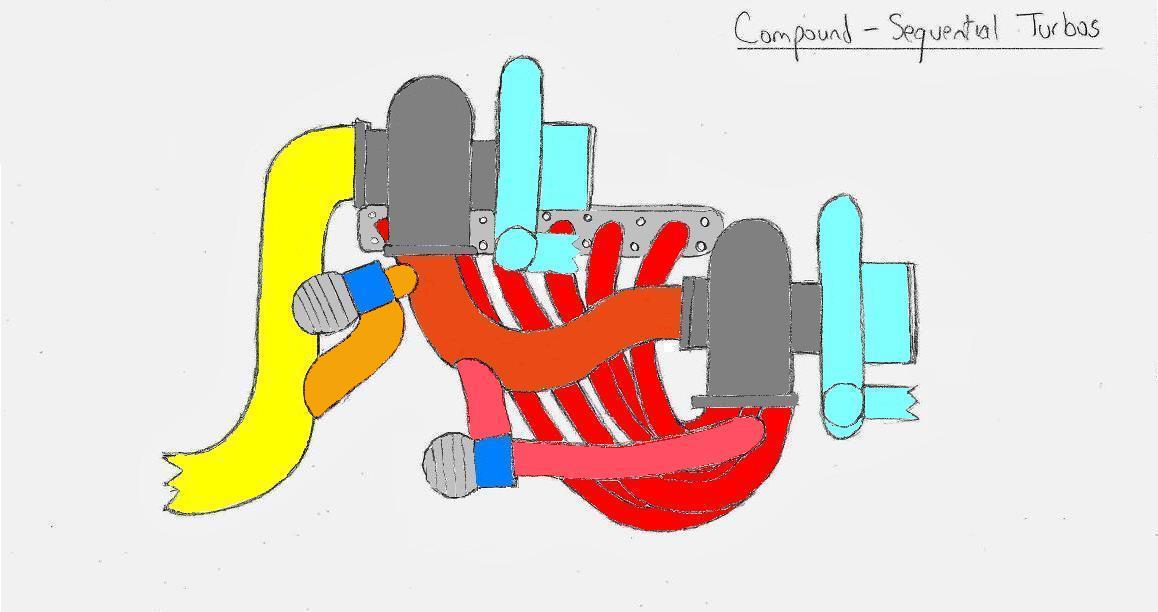

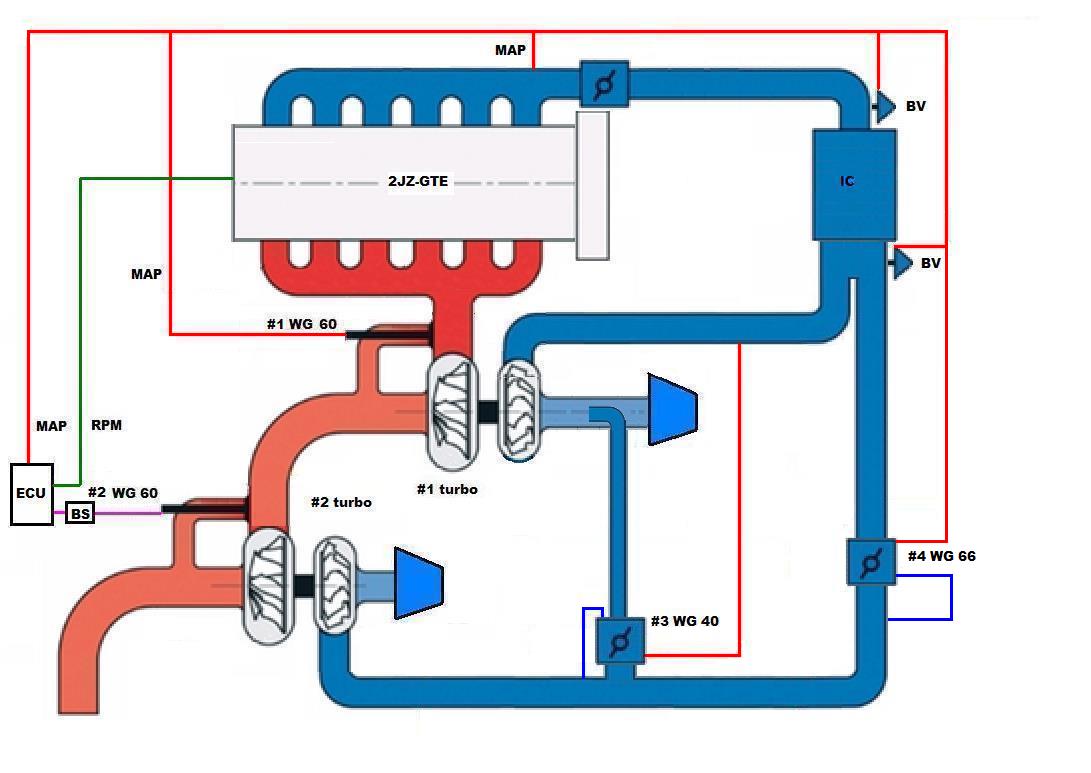

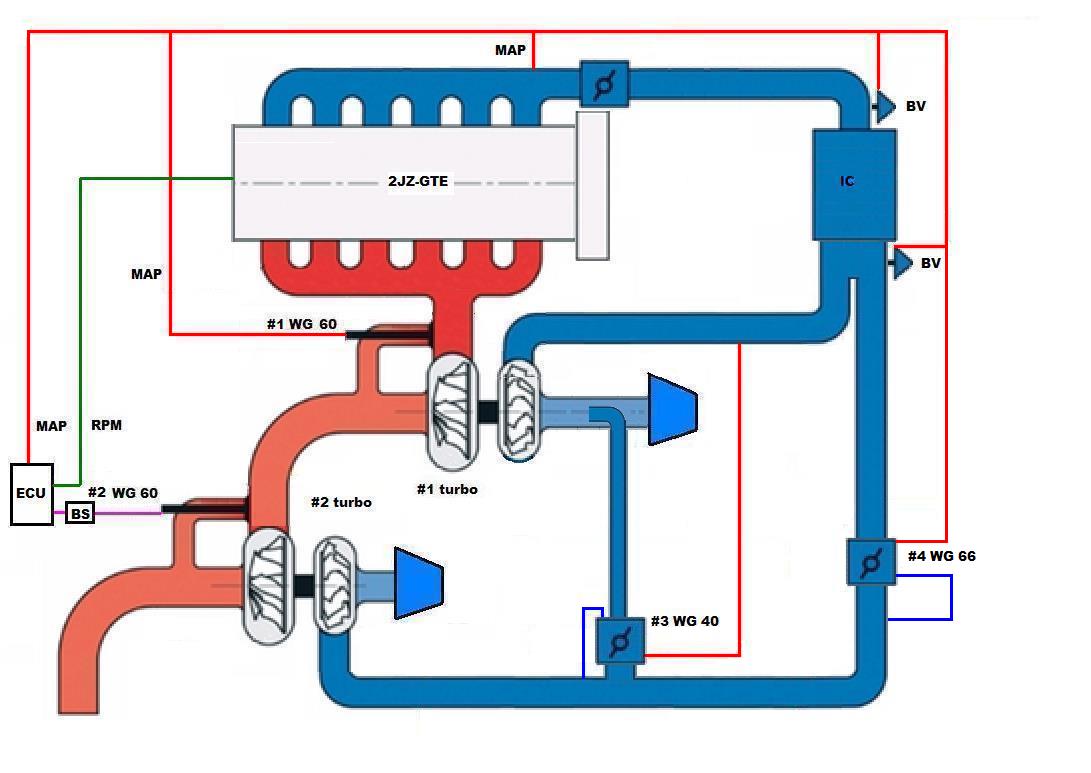

My design uses a proper high flowing manifold to the first turbo, eliminating the ugly and poor flowing log manifold seen in many sequential designs. Here's a drawing I did to show how my sequential setup will be implemented in practice on my 2JZ-GTE Supra engine. Note: the EGCV and the SCV are not shown.

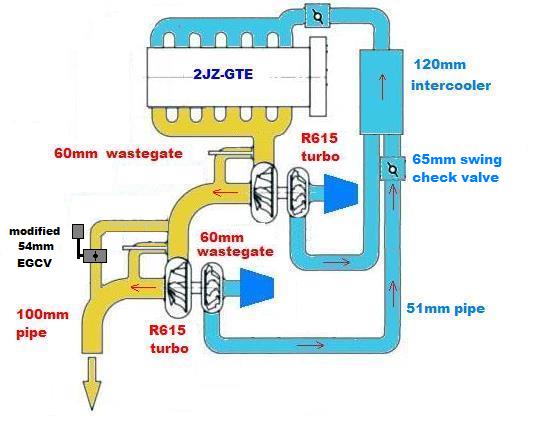

My design uses a 3.5" down pipe between the #1 and #2 turbo, a 4.0" down pipe for the #2 turbo and the 60mm wastegates have 3.0" pipes to maximize the flow.

Here is how the system should work:

Stage 1: both turbos are off boost and #2 turbo will be spinning fairly slowly. There is some flow through the swing check valve due to vacuum from the engine.

Stage 2: my setup will automatically transition to the 2nd (pre-spooling) stage as soon as the #1 turbo starts making boost due to increased exhaust flow in the #1 down pipe. Then a very small amount of boost from the #2 turbo will make its way past the swing check valve.

Stage 3: once the boost in #1 turbo climbs, it will automatically transition to the 3rd stage as the #2 turbo receives more waste exhaust gas from the #1 turbo. Then a large amount of boost from the #2 turbo will make its way past the swing check valve.

Stage 4: the #1 turbo is at full boost and the #2 turbo boost is quickly rising to full boost. The swing check valve is fully open to let the full flow from #2 turbo go to the engine.

All constructive comments and suggestions are welcome.

This sequential setup is basically a compound turbo setup on the exhaust side (but with identical size turbos) and a sequential setup on the intake side. This means you get all the advantages of a compound turbo setup for spooling the turbos, but with none of the disadvantages of the compound setup such as the boost being too high for a gas engine. Also both turbos are exactly the same size, so you don't get any issues with different size turbos fighting each other in the sequential setup and having the large one potentially overpowering the smaller one.

By spooling the second turbo with the gas exiting from the first turbo, the second turbo will spool much quicker then if it was just receiving some exhaust gas diverted from the first turbo, as most other sequential turbo systems do. This means that instead of having a big dip in the torque curve when the second turbo comes on-line, there should be little to no dip in the torque, resulting in a torque curve more like a large single turbo.

This setup is super simple and only requires 2 devices to be controlled, which is simpler then any other sequential turbo setup I've seen. There are two wastegates, one used for each turbo and they are set to exactly the same boost level. These wastegates need to be controlled separately as the two turbos will require different duty cycles on the wastegate to maintain the same boost level. This can be done with one aftermarket ECU as long as it has free outputs.

The factory 2JZ-GTE Exhaust Gas Control Valve (EGCV) is modified so that it is open when the actuator is not activated. This is so the #1 turbo has reduced back pressure so that it can spool faster. When the boost from the #1 turbo reaches 7psi, the actuator automatically closes and this allows the #2 turbo to start spooling.

The swing check valve (SCV) is used as a one way valve so that the boost pressure from the #1 turbo does not feed back through the #2 turbo.

My design uses a proper high flowing manifold to the first turbo, eliminating the ugly and poor flowing log manifold seen in many sequential designs. Here's a drawing I did to show how my sequential setup will be implemented in practice on my 2JZ-GTE Supra engine. Note: the EGCV and the SCV are not shown.

My design uses a 3.5" down pipe between the #1 and #2 turbo, a 4.0" down pipe for the #2 turbo and the 60mm wastegates have 3.0" pipes to maximize the flow.

Here is how the system should work:

Stage 1: both turbos are off boost and #2 turbo will be spinning fairly slowly. There is some flow through the swing check valve due to vacuum from the engine.

Stage 2: my setup will automatically transition to the 2nd (pre-spooling) stage as soon as the #1 turbo starts making boost due to increased exhaust flow in the #1 down pipe. Then a very small amount of boost from the #2 turbo will make its way past the swing check valve.

Stage 3: once the boost in #1 turbo climbs, it will automatically transition to the 3rd stage as the #2 turbo receives more waste exhaust gas from the #1 turbo. Then a large amount of boost from the #2 turbo will make its way past the swing check valve.

Stage 4: the #1 turbo is at full boost and the #2 turbo boost is quickly rising to full boost. The swing check valve is fully open to let the full flow from #2 turbo go to the engine.

All constructive comments and suggestions are welcome.

Last edited by V8KILR; 12-07-2013 at 02:28 PM.

#2

Here is a more detailed explanation of the stages that I think will occur:

1. When running off boost the engine will draw airflow through both turbos with the majority coming through the #1 turbo. The EGCV is open and all wastegates are closed. The swing check valve (SCV) will be partially open due to vacuum from the engine.

2. As the #1 turbo transitions onto boost the airflow will switch to all going through the #1 turbo. The EGCV is still open and all wastegates are closed. The SCV is probably now closed. The #2 turbo is still just idling.

3. When the #1 turbo reaches 7psi boost, the EGCV will close and all wastegates are still closed. This will increase the exhaust flow through the #2 turbo which will now start to speed up. The #1 turbo spool speed will decrease in the rate of increase, but it will still continue to increase boost pressure.

4. When the #1 turbo reaches around 15psi, the #2 turbo should start making boost. The EGCV and all wastegates are closed. The SCV may start to open shortly depending on how quickly the #2 turbo boost pressure backs up in the #2 intercooler pipe. A small amount of flow from the #2 turbo may then pass through the SCV.

5. When the #1 turbo reaches 35psi, the #1 wastegate will be opened under ECU control. The EGCV and #2 wastegate are closed. The SCV will be partially open.

6. When the #2 turbo reaches 35psi, the #2 wastegate will be opened under ECU control. The EGCV is closed. The SCV will be fully open.

1. When running off boost the engine will draw airflow through both turbos with the majority coming through the #1 turbo. The EGCV is open and all wastegates are closed. The swing check valve (SCV) will be partially open due to vacuum from the engine.

2. As the #1 turbo transitions onto boost the airflow will switch to all going through the #1 turbo. The EGCV is still open and all wastegates are closed. The SCV is probably now closed. The #2 turbo is still just idling.

3. When the #1 turbo reaches 7psi boost, the EGCV will close and all wastegates are still closed. This will increase the exhaust flow through the #2 turbo which will now start to speed up. The #1 turbo spool speed will decrease in the rate of increase, but it will still continue to increase boost pressure.

4. When the #1 turbo reaches around 15psi, the #2 turbo should start making boost. The EGCV and all wastegates are closed. The SCV may start to open shortly depending on how quickly the #2 turbo boost pressure backs up in the #2 intercooler pipe. A small amount of flow from the #2 turbo may then pass through the SCV.

5. When the #1 turbo reaches 35psi, the #1 wastegate will be opened under ECU control. The EGCV and #2 wastegate are closed. The SCV will be partially open.

6. When the #2 turbo reaches 35psi, the #2 wastegate will be opened under ECU control. The EGCV is closed. The SCV will be fully open.

#6

The diagram in the first post is a bit outdated as that was the first drawing I did before I refined the setup. There are now two wastegates that control the sequential operation, so the second turbo will reach manifold pressure before its flow is joined with the first turbo. The first turbo will not stall from exhaust restriction as that's how every compound turbo setup works.

#7

True compounds do not stall because the secondary turbine is larger to flow the already expanded and cooled exhaust without excessively restricting flow through the primary turbine. Plus, the primary turbo has extra load having to compress the already compressed air.

As your turbines are identical, the primary turbo will not have sufficient pressure drop across the turbine to maintain flow. Most of the exhaust will flow through the wastegate, equalizing pressure across the turbine and the primary turbo will stall.

In the absolute best case, you will have a very high drive pressure to boost pressure ratio and much less power than with a single turbo at the same boost. That is the reason it has NEVER been done on any OEM or race application.

Also, you do not need a blowoff valve before and after the aftercooler.

Last edited by OM617; 07-27-2014 at 04:32 AM.

#8

You are correct based on my first post information, but my exhaust side setup is not the same as my first post as I've learned a lot about compound turbo setups since making that post.

What I have actually built is a true compound system on the exhaust side, so the exhaust side will work just fine and not have any of the issues that you mention. Hopefully I will be dynoing it in a couple of weeks to see if the sequential control also works.

There are two blowoff valves on my car because they are both quite small. One big one would do the job as you say.

What I have actually built is a true compound system on the exhaust side, so the exhaust side will work just fine and not have any of the issues that you mention. Hopefully I will be dynoing it in a couple of weeks to see if the sequential control also works.

There are two blowoff valves on my car because they are both quite small. One big one would do the job as you say.

#10

[/IMG]

[/IMG] [/IMG]

[/IMG] [/IMG]

[/IMG] [/IMG]

[/IMG] [/IMG]

[/IMG] [/IMG]

[/IMG] [/IMG]

[/IMG] [/IMG]

[/IMG]