Holset VGT HE351VE Controller

#51

CivicTsi, you know about aero's experiences with the turbo right? like this datalog, just look at the top log and disregard the rest:

He's using a 9psi actuator on the VGT arm. You can see boost shoots up to 9 psi then the rack opens and the boost builds slowly to 14psi where the external wastegate opens. He says the boost creeps up to 24psi without gate. As for me, my turbo's still sitting in a box outside.

I'm using a PIC16F88, just a little 18 pins chip with ADC's. I do have a 16F877 (40 pin thing with a lotta features) too but I doubt I'll need to use that for this project.

Do you think your system is fast enough to avoid boost spikes or fluctuating boost?

turboedmav, I bought this book and learned most of the stuff to do with PIC's off that. That book focuses on a compiler called PICBasic which is similar to 'basic' programming language or something. It's really simple to use like CivicTsi's PICaxe code. Without PICBasic you'd be programming in assembly code or in C, there's a PIC C-lite compiler in the package I bought but I never bothered to use it since all the documentation I got with the package was for PICBasic Pro. The documentation that comes with the compiler is good enough to get you started but the book is nice as it gives you a few example circuits and set up tips.

He's using a 9psi actuator on the VGT arm. You can see boost shoots up to 9 psi then the rack opens and the boost builds slowly to 14psi where the external wastegate opens. He says the boost creeps up to 24psi without gate. As for me, my turbo's still sitting in a box outside.

I'm using a PIC16F88, just a little 18 pins chip with ADC's. I do have a 16F877 (40 pin thing with a lotta features) too but I doubt I'll need to use that for this project.

Do you think your system is fast enough to avoid boost spikes or fluctuating boost?

turboedmav, I bought this book and learned most of the stuff to do with PIC's off that. That book focuses on a compiler called PICBasic which is similar to 'basic' programming language or something. It's really simple to use like CivicTsi's PICaxe code. Without PICBasic you'd be programming in assembly code or in C, there's a PIC C-lite compiler in the package I bought but I never bothered to use it since all the documentation I got with the package was for PICBasic Pro. The documentation that comes with the compiler is good enough to get you started but the book is nice as it gives you a few example circuits and set up tips.

#53

I'm still working on the PWM route to control the factory electronics. No success yet. I'm doubting more and more that this thing is preprogrammed to additionally accept PWM. I'll give it a few more tries at varying pins and frequencies then I'm just going to concentrate on installing and tuning the system I made. As for boost control, it seems that other people who've put this turbo on gasoline engines have had to install an additional wastegate. I wonder if this is really needed. Perhaps people didn't have the vanes open the whole way in order to decrease boost. Anyone have personal experience with this?

I've tried researching to find out the approximate difference in exhaust gas volumes produced by both gasoline and diesel engines -given the same displacement, that is- with no clear results so far... what I'd like to know is how many more (or less) CFMs come out of a diesel engine vs a gas engine the same size. I know compression ratios in diesels are higher so I'm gessing exhaust flows are higher as well... thing is, I have no idea by how much these flows differ... and if tey're higher in diesels, this contradicts what everybody says about instlling a wastegate in a gas engine... perhaps what makes it necessary is not so much exhaust gas volume but the expansion rate once they leave the combustion chamber... or maybe it is the amount of energy still available in gasoline exhasut to push the turbine vs the diesel's colder exhaust... (dunno really) ... wish I could enlist someone's help who could do the math for me... I'm dizzy already!

If we had this numbers (just ballpark figures) we could then plot them against a turbine map ans have a slightly better understanding of where we stand with our gassers. "Aero" did some investigating and concluded the exhaust AR goes from an incredible 0.14 to a whopping 1.83!!! This is roughly from 3 sq/cm when fully closed to 25 sq/cm when fully open.

Last edited by Turboedmav; 05-17-2010 at 03:12 AM.

#54

CivicTsi, you know about aero's experiences with the turbo right? like this datalog, just look at the top log and disregard the rest:

He's using a 9psi actuator on the VGT arm. You can see boost shoots up to 9 psi then the rack opens and the boost builds slowly to 14psi where the external wastegate opens. He says the boost creeps up to 24psi without gate. As for me, my turbo's still sitting in a box outside.

I'm using a PIC16F88, just a little 18 pins chip with ADC's. I do have a 16F877 (40 pin thing with a lotta features) too but I doubt I'll need to use that for this project.

Do you think your system is fast enough to avoid boost spikes or fluctuating boost?

turboedmav, I bought this book and learned most of the stuff to do with PIC's off that. That book focuses on a compiler called PICBasic which is similar to 'basic' programming language or something. It's really simple to use like CivicTsi's PICaxe code. Without PICBasic you'd be programming in assembly code or in C, there's a PIC C-lite compiler in the package I bought but I never bothered to use it since all the documentation I got with the package was for PICBasic Pro. The documentation that comes with the compiler is good enough to get you started but the book is nice as it gives you a few example circuits and set up tips.

He's using a 9psi actuator on the VGT arm. You can see boost shoots up to 9 psi then the rack opens and the boost builds slowly to 14psi where the external wastegate opens. He says the boost creeps up to 24psi without gate. As for me, my turbo's still sitting in a box outside.

I'm using a PIC16F88, just a little 18 pins chip with ADC's. I do have a 16F877 (40 pin thing with a lotta features) too but I doubt I'll need to use that for this project.

Do you think your system is fast enough to avoid boost spikes or fluctuating boost?

turboedmav, I bought this book and learned most of the stuff to do with PIC's off that. That book focuses on a compiler called PICBasic which is similar to 'basic' programming language or something. It's really simple to use like CivicTsi's PICaxe code. Without PICBasic you'd be programming in assembly code or in C, there's a PIC C-lite compiler in the package I bought but I never bothered to use it since all the documentation I got with the package was for PICBasic Pro. The documentation that comes with the compiler is good enough to get you started but the book is nice as it gives you a few example circuits and set up tips.

#55

As for the speed of my system, I think it will do just fine. There is a delay of about 100ms until the vane is homed in on where it needs to be. If not, I guess I'll find out soon.

#57

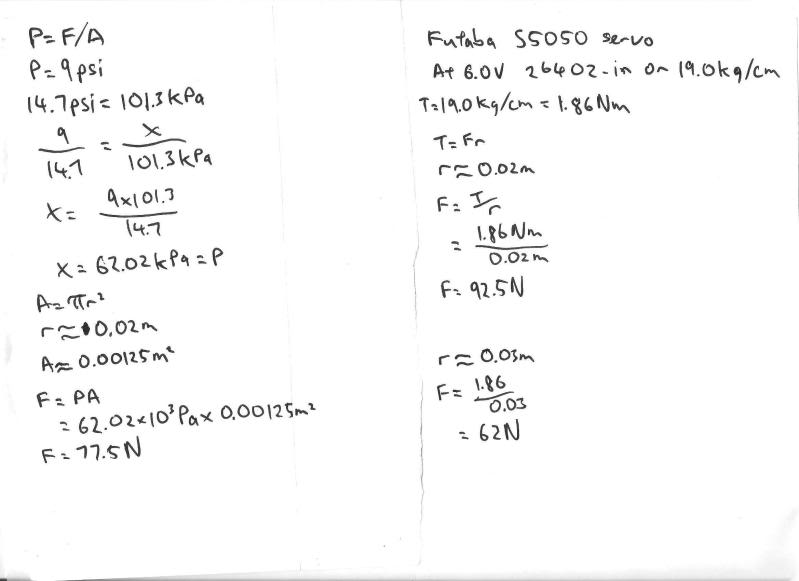

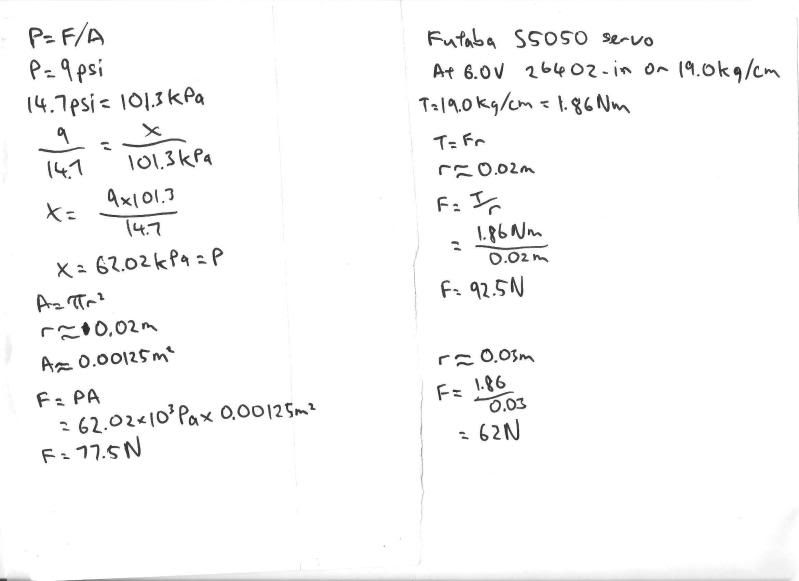

On the left column, what area are you measuring? I'm guessing that is the area of the diaphragm on a conventional wastegate actuator and that 77.5N is the force achieved by it. On the right column, are 2 and 3 cm the radius of the servo's swing? If so, this looks right to me. What is the heat tolerance of your servo?

As for the speed of my system, I think it will do just fine. There is a delay of about 100ms until the vane is homed in on where it needs to be. If not, I guess I'll find out soon.

As for the speed of my system, I think it will do just fine. There is a delay of about 100ms until the vane is homed in on where it needs to be. If not, I guess I'll find out soon.

Servo heat tolerance: no idea. Their website don't say anything about temps. I found a servo that's cheaper with higher torque with the option of upgrading to robotics servos with even more torque at higher voltage. I'm going to try test out the algorithm and heat tolerance by running a servo in place of the wastegate actuator, mounted off the compressor housing in a similar to what I would like to do with the holset. That way I can sorta get an idea of whether it's going to work (or melt away or not be quick enough) before I install the 351VE.

How big an engine are you planning on running the turbo on? I've got a 1.8 and a 38mm wastegate, you think it'll be enough?

#58

I'm planning on using my HE351VE on a Mexican 2.5 dodge Shadow but... out of curiosity... you guys think using this turbo on a Ford 5.0L is crazy?... I'd be looking into very low boost levels for this stock block and internals (6-10 psi max) ... I asked people in other forums and they said: "it'll spool up stupid fast and behave like a supercharger because of the larger displacement... (not necesarily a bad thing, right?) and it'll be trying to make boost from the very bottom end" ... but I wonder how bad that'll be for the turbo once the engine goes into higher revs? barking? surging? choking? or how badly will it strangle the engine in the top end? even with vanes fully open... umhhh... what you guys think? ... Will I have to fabricate a turbo manifold with multiple leaks on purpose and use a ridiculously restrictive exhaust system to keep the thing from exploding into tiny bits? LOL... just kidding... (or not ) ...

) ...

That's why I am interested in knowing more about gas vs diesel exhaust flows... just to get a ball park figure on how this thing might behave on a larger gas engine... I know a huge wastegate will be needed... but ... won´t that mean the turbo will operating out of good efficiency islands most of the time? .... all ideas, feedback and slaps on my head are welcome.

) ...

) ... That's why I am interested in knowing more about gas vs diesel exhaust flows... just to get a ball park figure on how this thing might behave on a larger gas engine... I know a huge wastegate will be needed... but ... won´t that mean the turbo will operating out of good efficiency islands most of the time? .... all ideas, feedback and slaps on my head are welcome.

#59

You have a v8. You already have torque down low and you want more? You's crazy. I'd love to throw a 302 into my RX-7 and leave it NA. but I were to turbo a 302 would run a hx40 or something and not bother with a VGTurbo. Use a 451VE if you really wanted to use a VGTurbo. I'm running this turbo because it makes 400hp+ with much less lag than a conventional turbo.

Super rough calcs from here using this compressor map suggests that the compressor is too small to run 10psi on a 302. It seems perfect for my application though.

Super rough calcs from here using this compressor map suggests that the compressor is too small to run 10psi on a 302. It seems perfect for my application though.

#60

Damn!!... I'll slap it to the Shadow for sure ... BUT if I have enough time and feel like experimenting somethin' stupid... I might play with my mig welder and fabricate a little here and there just to see how it turns out... I sorta figured that this turbo being capable of boost levels around 25-30psi on big diesels... then my conclusion was that 10 psi (or a little less) would be feasible in larger displacement gasssers like the 302...  I gotta re-learn how to plug my intake flow figures onto those maps... read about it a few years ago... I need to brush up on these things already...

I gotta re-learn how to plug my intake flow figures onto those maps... read about it a few years ago... I need to brush up on these things already...

Yes... got torque down low with the 5.0L... but c'mon... who are we kiddin'?... this stuff is addictive, the more you get, the more you want, don't you? ... and 400lbft doesn't sound soooo bad... sends chills down my spine already... more torquey = more fun to drive... yes!

I gotta re-learn how to plug my intake flow figures onto those maps... read about it a few years ago... I need to brush up on these things already...

I gotta re-learn how to plug my intake flow figures onto those maps... read about it a few years ago... I need to brush up on these things already...Yes... got torque down low with the 5.0L... but c'mon... who are we kiddin'?... this stuff is addictive, the more you get, the more you want, don't you? ... and 400lbft doesn't sound soooo bad... sends chills down my spine already... more torquey = more fun to drive... yes!