welding aluminum with OA

#11

no its not lol its "the preffered method of welding" for that company because that's what they sell.

90% of that industry is MIG welding, 2% pulsed mig, 8% tig.

Kent White, The Tinman

Just like this bozo:

1) he's lieing out his *** on his frontside/backside pictures. he's sickeningly using incorrect welding techniques to make the welds come out terrible

2) Argon backpurging is cheap. You're increasing your rate of argon consumption by what? 20-25%?

3) You CAN weld alu & SS without a backpurge provided you use the specified flux rods for it. which guess what! are still less expencive than the ---- he's spewing.

90% of that industry is MIG welding, 2% pulsed mig, 8% tig.

Kent White, The Tinman

Just like this bozo:

1) he's lieing out his *** on his frontside/backside pictures. he's sickeningly using incorrect welding techniques to make the welds come out terrible

2) Argon backpurging is cheap. You're increasing your rate of argon consumption by what? 20-25%?

3) You CAN weld alu & SS without a backpurge provided you use the specified flux rods for it. which guess what! are still less expencive than the ---- he's spewing.

#12

well supposedly it gives a softer weld for applications such as welding chopper gas tanks that will see a lot of vibration. the tig process gives you a harder weld that is more prone to cracking on the streets.

after they aneal and soften the metal OA keeps its soft.

i ordered the kit and he welds on the video and shows the underside. looks just like the topside. you can tell its the underside but its still stacked.

after they aneal and soften the metal OA keeps its soft.

i ordered the kit and he welds on the video and shows the underside. looks just like the topside. you can tell its the underside but its still stacked.

#16

i tried again tonight and actually got some penetration. (5 digit penetration hahah)

naw but i hammer tested it and it didnt break. tested on some cast aluminum IC piping off of a saab. once i get better ill fix my dizzy and then do my IC pipes all around.

sorry no pix tonight. ill get them manana though. for sho.

naw but i hammer tested it and it didnt break. tested on some cast aluminum IC piping off of a saab. once i get better ill fix my dizzy and then do my IC pipes all around.

sorry no pix tonight. ill get them manana though. for sho.

#17

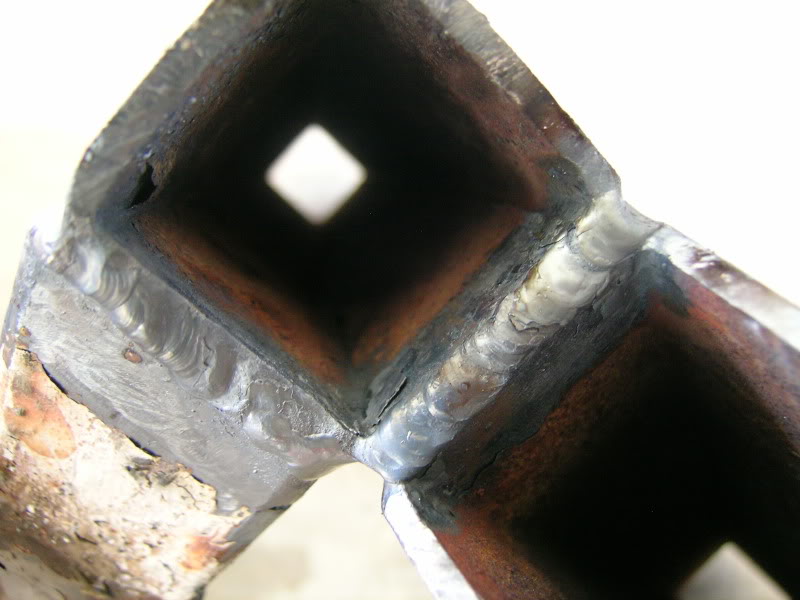

made a jack stand today. these are my good welds. mild steel square tubing.

this is my first aluminum weld. super thin material. flux mixture was all wrong. it wasnt easy

2nd attempt. thicker cast aluminum piping. super rich flux mix. remembered to put it on the inside of the pipe as well. worked out a little better.

aluminum is super easy to overheat. it will start to sag and fall through. right when it does that you gotta pull away.