Tig question: wg flange/valve seat bead cracking and I'm unsure why

#1

I'm finishing up a mild steel sched 40 manifold and for some reason the flange/valve seat for the generic 40mm wastegate will not cleanly attach to the schedule 40 pipe. I can lay a bead and it cracks almost instantly. The flange appears to be cast steel. I'm certain many of you guys have welded them so what's up? Am I going to have to heat the hell out of it before and allow it to slowly cool? I've welded cast before but this one is a PITA!

Is that just what comes with purchasing a cheap *** wastegate? Is it stainless steel by chance and if so would it make a difference? I'm using er70s2 filler.

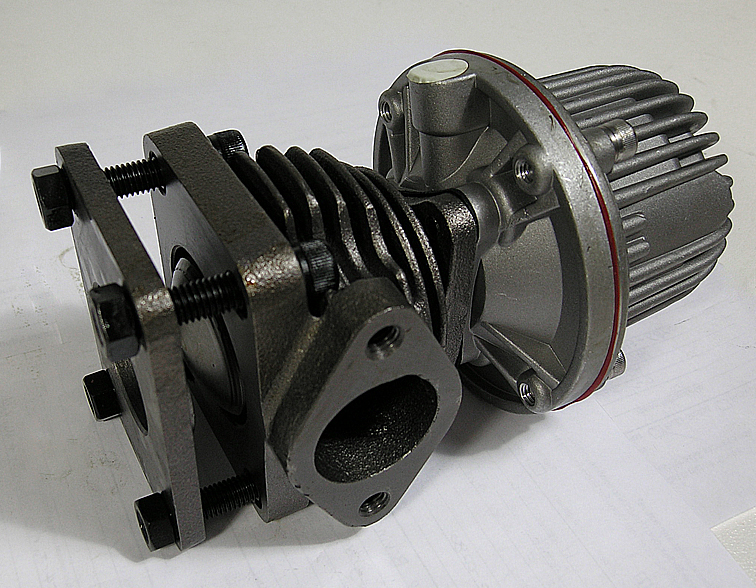

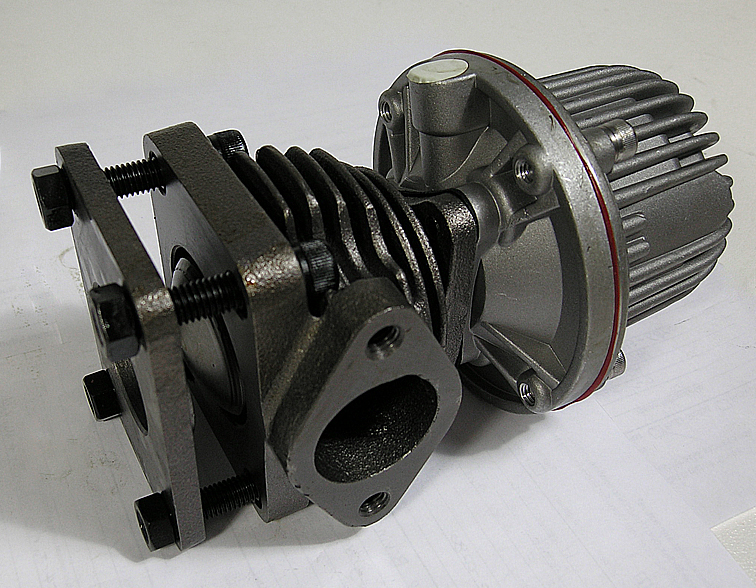

Here's a pic of the same style wastegate:

Is that just what comes with purchasing a cheap *** wastegate? Is it stainless steel by chance and if so would it make a difference? I'm using er70s2 filler.

Here's a pic of the same style wastegate:

#3

The manifold is sched 40 mild steel.

Is the wastegate body and flange stainless steel? If so then you may have a point. If not then I'm simply welding mild steel to mild steel although the flange may be cast.

I just tested it with a magnet and it sticks so I assume it's mild steel. In that case why is it cracking?

Is the wastegate body and flange stainless steel? If so then you may have a point. If not then I'm simply welding mild steel to mild steel although the flange may be cast.

I just tested it with a magnet and it sticks so I assume it's mild steel. In that case why is it cracking?

#4

Show me the weld.

Assuming you know what you're doing.

Assuming you know what you're doing.

- your flange is probably very low quality cast steel, you're welding cast iron

- Inclusions in your weld

- Pre-heat to 350-400*F

- Post heat to 350-400*F, and/or immediately place in a bucket of sand to insulate

- Grind everything before welding, especially the wastegate

- Skip weld. Weld half an inch, move to the opposite side of the workpiece

- Peen the weld immediately after welding

#6

Thanks guys I'll pre/post heat and give that a shot. I did skip weld but eventually they start to crack. The welds are cracking right in the middle. There are sections that remain uncracked but they eventually crack as other areas fuse and hold.

I can't peen the weld because it begins to crack before I can even lay down the torch and grab a hammer.

Do you make mild steel flanges that include the valve seat for the wastegate as shown here?

I can't peen the weld because it begins to crack before I can even lay down the torch and grab a hammer.

Originally Posted by weiRtech

scrap the cast flange and buy a regular mild steel one.

Thread

Thread Starter

Forum

Replies

Last Post

turboDA6

General Discussion

15

07-22-2005 03:00 PM