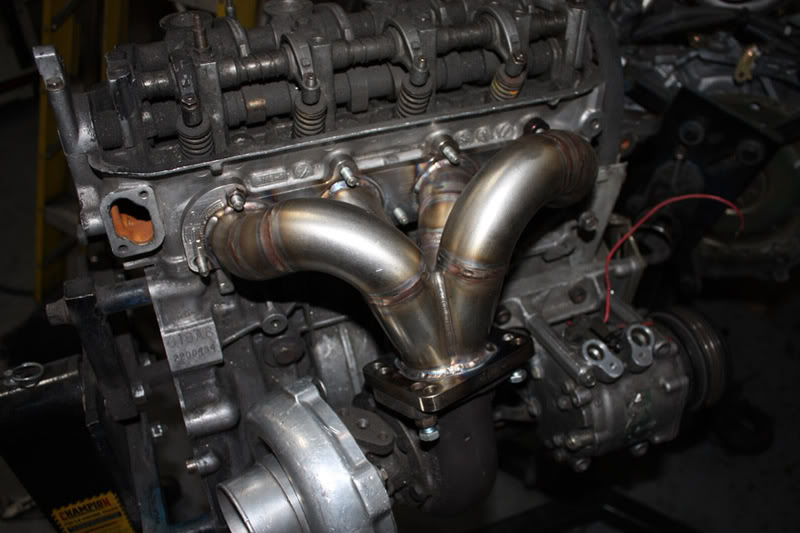

Spoolin performance welding update

#4

you don't seem consistent at all.

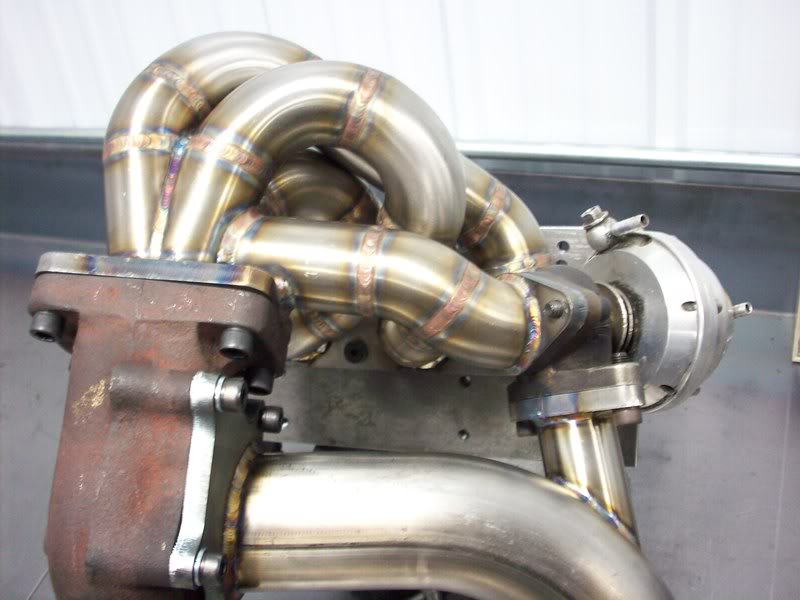

now i understand tig welding is hard and all, but man you have some spots that are huge wide welds then some are thin and looks good, but it just throws the whole look off when there not the same looking.

alos practice your starts and stops, there so noticable it's crazy.

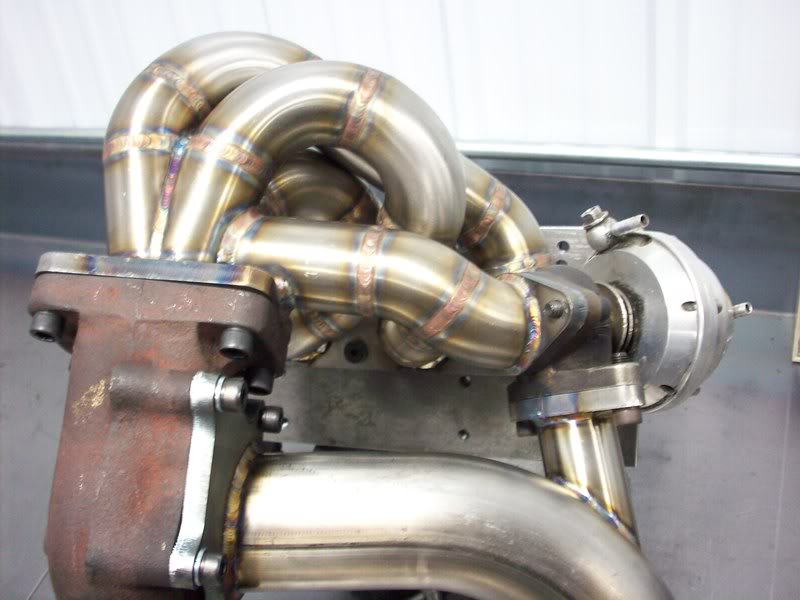

and will you stop running those damn dual turbo flanges. t4's are Way different how do you think that a manifold will perform if it is not designed for that given size turbo (T25,T3,T4)

please explain?

now don't take this the wrong way, but it is rare that i'm impressed with peoples welds.

now i understand tig welding is hard and all, but man you have some spots that are huge wide welds then some are thin and looks good, but it just throws the whole look off when there not the same looking.

alos practice your starts and stops, there so noticable it's crazy.

and will you stop running those damn dual turbo flanges. t4's are Way different how do you think that a manifold will perform if it is not designed for that given size turbo (T25,T3,T4)

please explain?

now don't take this the wrong way, but it is rare that i'm impressed with peoples welds.

#5

Originally Posted by turbob16hatch

you don't seem consistent at all.

now i understand tig welding is hard and all, but man you have some spots that are huge wide welds then some are thin and looks good, but it just throws the whole look off when there not the same looking.

alos practice your starts and stops, there so noticable it's crazy.

and will you stop running those damn dual turbo flanges. t4's are Way different how do you think that a manifold will perform if it is not designed for that given size turbo (T25,T3,T4)

please explain?

now don't take this the wrong way, but it is rare that i'm impressed with peoples welds.

now i understand tig welding is hard and all, but man you have some spots that are huge wide welds then some are thin and looks good, but it just throws the whole look off when there not the same looking.

alos practice your starts and stops, there so noticable it's crazy.

and will you stop running those damn dual turbo flanges. t4's are Way different how do you think that a manifold will perform if it is not designed for that given size turbo (T25,T3,T4)

please explain?

now don't take this the wrong way, but it is rare that i'm impressed with peoples welds.

#6

now do you expect me to post in every thread that i give welding feedback in? sounds dumb.

Now i never have said i am the best welder in the world, but i listen to people when i get feedback and i hope other do the same, only way you can learn.

again i go for consistent welds as it makes the peice look better overall.

again no offence to spoolin but he made a thread in welding fab on HMT, this isn't honda tech where everone will ride your nuts.

Now i never have said i am the best welder in the world, but i listen to people when i get feedback and i hope other do the same, only way you can learn.

again i go for consistent welds as it makes the peice look better overall.

again no offence to spoolin but he made a thread in welding fab on HMT, this isn't honda tech where everone will ride your nuts.

#7

Originally Posted by turbob16hatch

you don't seem consistent at all.

now i understand tig welding is hard and all, but man you have some spots that are huge wide welds then some are thin and looks good, but it just throws the whole look off when there not the same looking.

alos practice your starts and stops, there so noticable it's crazy.

and will you stop running those damn dual turbo flanges. t4's are Way different how do you think that a manifold will perform if it is not designed for that given size turbo (T25,T3,T4)

please explain?

now don't take this the wrong way, but it is rare that i'm impressed with peoples welds.

now i understand tig welding is hard and all, but man you have some spots that are huge wide welds then some are thin and looks good, but it just throws the whole look off when there not the same looking.

alos practice your starts and stops, there so noticable it's crazy.

and will you stop running those damn dual turbo flanges. t4's are Way different how do you think that a manifold will perform if it is not designed for that given size turbo (T25,T3,T4)

please explain?

now don't take this the wrong way, but it is rare that i'm impressed with peoples welds.

also doesnt help i was moving around from testing the dynasty 200DX vs my usual synchrowave 200

the dynasty inverter definitely is a kick *** welder but i had difficulties readjusting my welding technique to the older transformer based welder. With the inverters, the arc is much more stable and the ability to keep small beads are amazing.

while you may have the advantage of weld consistency in start and stops and bead size.

your beads are not " uniformly" spaced ---- it is only the weld color and the rainbows that hide the true contours of your weld beads. The filler rod i use is not your typical 316 or 309 and will not normally provide many " rainbows" for ooh's and ahh's.

I am not perfect. nor are you. i believe the only one that gets close is full-race when it comes to extreme consistency but neither I or you charge those types of prices.

Lastly, i have straight t4 flanges also for those who wish to have full-t04E based manifolds i use the dual pattern flange because

1) lets the consumer have a choice whether to run a t3 or t4 based turbo

2) marketability

4) doesn't cost me or my consumer anymore to have machined then std t3 based flange.

#8

yeah i still work everyday to get that robot like consistency that i strive for. lol but i don't think that will come anytime soon.

yeah i tried to use 316 rod before and the color was crazy but the puddle felt like ---- compared to 308. so i went back to 308.

I also have found that people look the colored welds, and getting the color has come down to when i pull the torch away from the weld. really funny how welds suck if there not rainbow colored? right?

I have been looking into getting a 200dx is it worth it?

I'm pretty partial to my sync 200.

yeah i tried to use 316 rod before and the color was crazy but the puddle felt like ---- compared to 308. so i went back to 308.

I also have found that people look the colored welds, and getting the color has come down to when i pull the torch away from the weld. really funny how welds suck if there not rainbow colored? right?

I have been looking into getting a 200dx is it worth it?

I'm pretty partial to my sync 200.

#9

Originally Posted by turbob16hatch

yeah i still work everyday to get that robot like consistency that i strive for. lol but i don't think that will come anytime soon.

yeah i tried to use 316 rod before and the color was crazy but the puddle felt like ---- compared to 308. so i went back to 308.

I also have found that people look the colored welds, and getting the color has come down to when i pull the torch away from the weld. really funny how welds suck if there not rainbow colored? right?

I have been looking into getting a 200dx is it worth it?

I'm pretty partial to my sync 200.

yeah i tried to use 316 rod before and the color was crazy but the puddle felt like ---- compared to 308. so i went back to 308.

I also have found that people look the colored welds, and getting the color has come down to when i pull the torch away from the weld. really funny how welds suck if there not rainbow colored? right?

I have been looking into getting a 200dx is it worth it?

I'm pretty partial to my sync 200.

yep !! all my welds pretty much stay consistent with gold. except as of lately, i maintenance my syncro 200 and changed over the contact points. machine went weird on me and recently set itself back to running smooth again. no idea what the hell it was but it infuriated me for a good day when i'd do test runs and the arc was stable for nothing.

made me feel like either i got used to the 200DX or my machine was somewhat jacked up.

in the end it was jacked up after i let other people /welders i know use it and they confirmed it was very inconsistent.

the 200DX is definitely something when it comes to aluminum. love all the settings that can be done. def make someone look like much more of a welder than they really are.

the stainless welding is extremely SMOOTH and dead silent.

i'd love to purchase me a 200DX except the whole economy and $$$ thing

with the "colors"

i've noticed other company's who have extreme colors/tiger stripping in their welds. but upon up close inspection. I wouldn't feel safe with it . the consistency is horrible but the colors and tiger stripping def made it look " snazzy" in pictures.

#10

Yeah i wish people took good picture like you do not hide them with a shitty camera.

I have a line on a 200dx for $1300 and with the increased AL welding i have coming my way i thought it would be nice with the settings it has available.

I have a line on a 200dx for $1300 and with the increased AL welding i have coming my way i thought it would be nice with the settings it has available.