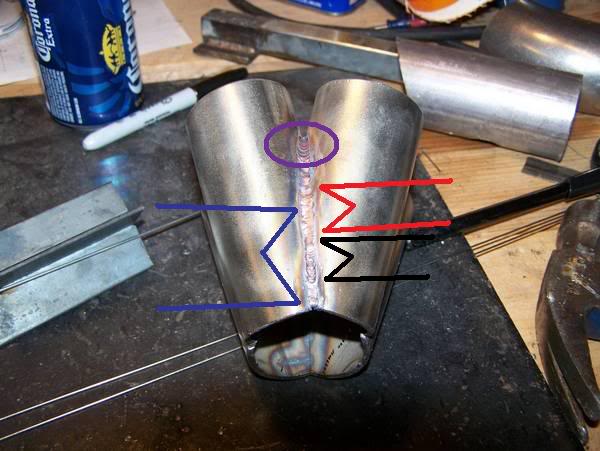

My first collector

#4

Black too much rod

Red way too hot

Blue way too cold

Grey poor start & stops and/or inconsistant rod application

Orange undercut, incorrect electrode motion/angles

Purple close but incorrect electrode distance

Green good

Ditto CS

Weld hotter and faster

Filler angles are wrong and/or inconsistent when you get it close

Electrode distance is all over the board, travel angle is very inconsistant, work angle is somewhat inconsistant, travel is inconsistant.

Basically um, too much playing with everything after the first mistake, or base metal change (root curves downward while walls curve in) is made. Concentrate very hard on the weld puddle and keep all your angles correct. Weld the next one hotter and move faster. Until you can do the entire thing plan on giving yourself one restart right before the curve drops off.

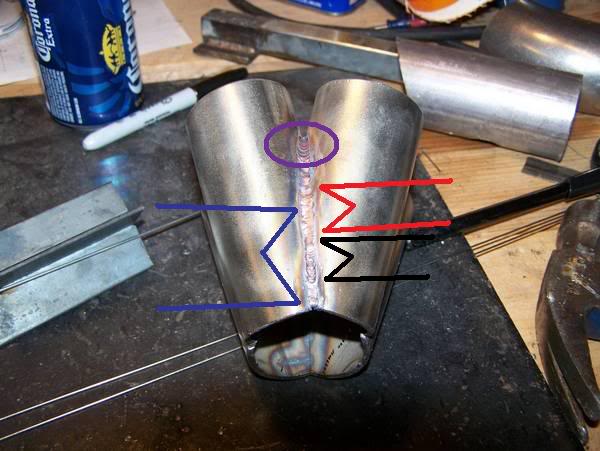

Looks aight.

Red way too hot

Blue way too cold

Grey poor start & stops and/or inconsistant rod application

Orange undercut, incorrect electrode motion/angles

Purple close but incorrect electrode distance

Green good

Ditto CS

Weld hotter and faster

Filler angles are wrong and/or inconsistent when you get it close

Electrode distance is all over the board, travel angle is very inconsistant, work angle is somewhat inconsistant, travel is inconsistant.

Basically um, too much playing with everything after the first mistake, or base metal change (root curves downward while walls curve in) is made. Concentrate very hard on the weld puddle and keep all your angles correct. Weld the next one hotter and move faster. Until you can do the entire thing plan on giving yourself one restart right before the curve drops off.

Looks aight.

#5

Wow, awesome. Thanks so much for the help. I know my welding has a long way to go and I apreciate all of the words of wisdom. This is all done on a HF Tig to which makes it a little more challanging.

#7

How far should the electrode be and what angle? It seems if I cool it down anymore, I get a puddle on both pieces of metal but they wont join. Thats when I add rod. I am trying to add as little rod as possible. I need to keep working on it  Thanks for the help and I will post some more pics.

Thanks for the help and I will post some more pics.

Thanks for the help and I will post some more pics.

Thanks for the help and I will post some more pics.

#8

You don't want to cool it down more, most of it was abit too cold to begin with.

The tungsten stick-out can varry with the size & type of cup/gas setup. Say 1/16-3/16" on a smaller cup without a gas lens.

Arc length varries. What is it, how hot? For this kind of stuff, if you're in the right heat range say no more than 3/16" and if you get too close, you'll know it. The tungsten jumps the arc into the weld and the base metal jumps to the tungsten.

The tungsten stick-out can varry with the size & type of cup/gas setup. Say 1/16-3/16" on a smaller cup without a gas lens.

Arc length varries. What is it, how hot? For this kind of stuff, if you're in the right heat range say no more than 3/16" and if you get too close, you'll know it. The tungsten jumps the arc into the weld and the base metal jumps to the tungsten.

#10

In the case of all these types of joints. The work angle of the electrode should always be at a 0*. (As in a 90* angle to the joint) It should not be offset.

The travel (push) angle should be 15-20*.

Well, if you want to weld it by the book you'll want 1/16-1/8" stickout. (That cup wont give you much) 105-115amps. Arc length no more than 1/8"

Most guys making these probably would weld that @ 30-60amps because they can't move fast enough. So... Gotta get moving if you're going to do it well.

If you have trouble keeping the arc length under 1/8" throw a cheater lens in the helm so you can actually see what you're doing.

The travel (push) angle should be 15-20*.

Well, if you want to weld it by the book you'll want 1/16-1/8" stickout. (That cup wont give you much) 105-115amps. Arc length no more than 1/8"

Most guys making these probably would weld that @ 30-60amps because they can't move fast enough. So... Gotta get moving if you're going to do it well.

If you have trouble keeping the arc length under 1/8" throw a cheater lens in the helm so you can actually see what you're doing.