Someone has the a6 wheeze picture?

#1

You remember the a6 wheeze Abaz did 2 years ago i think? Well i was looking for it and the pics are gone!

I'd like to know if somone or Abaz could send them to me or rehost them...

I'm looking mostly for the intake manifold part but i'd like the rest of the pics as well

my email adress: labatt50 @ mail.com (without space )

)

I'd like to know if somone or Abaz could send them to me or rehost them...

I'm looking mostly for the intake manifold part but i'd like the rest of the pics as well

my email adress: labatt50 @ mail.com (without space

)

)

#2

#4

i suck at life... found them

https://www.homemadeturbo.com/2005/wheeze/

but there is a lot more here

https://www.homemadeturbo.com/pictures/

i relink all the pics with the good address

https://www.homemadeturbo.com/2005/wheeze/

but there is a lot more here

https://www.homemadeturbo.com/pictures/

i relink all the pics with the good address

Originally Posted by AbaZ

Well some of you know I've been working on a D16a6 NA project this past month. I had a few problems at the end but I finally got everything pretty much dialed in. First off people are going to ask "wtf a all motor project and why D-series?" heh.. To answer the question this is kind of a unique project, I really wont go into details on why I built it the way I did and what its really for. My build consisted of looking stock from the outside and using stock OEM parts. This engine isnt even staying in my car for that long so some stuff will be changed later.

Anyways Onto the Mighty D project, lol

Starting off with a 88 D16a6 from a Civic SI (150k miles) I recently did a ZC swap in for a customer. Putting out a blistering 105hp at the crank maybe 90ish whp.

Engine was pretty dirty since it was pretty high milage, I went ahead and dissasembled the engine.

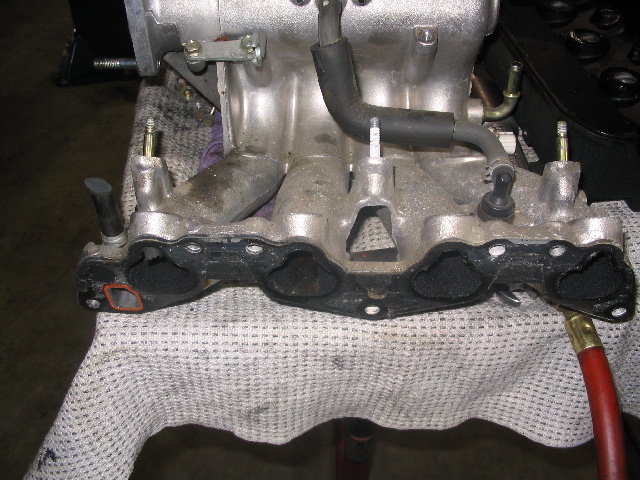

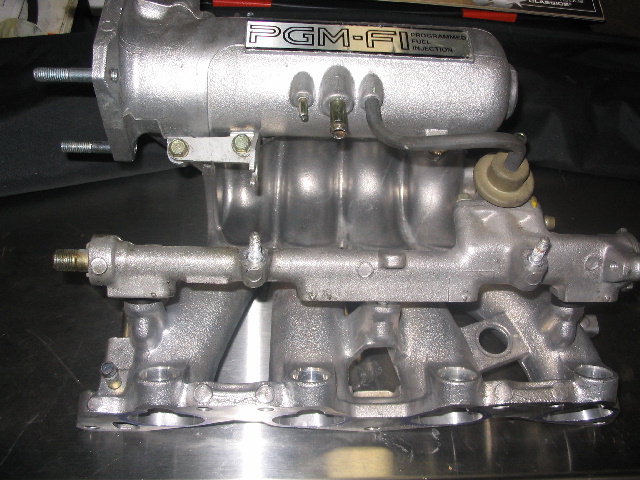

Stock Intake manifold all carboned up

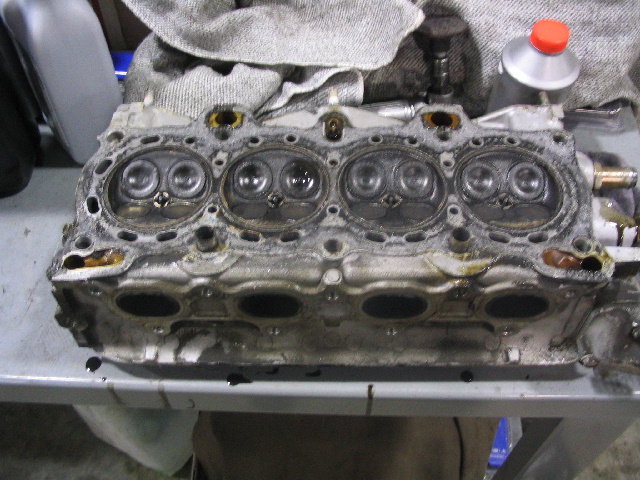

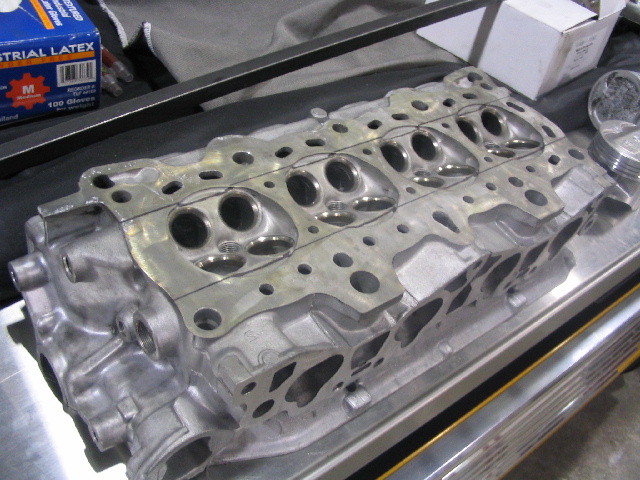

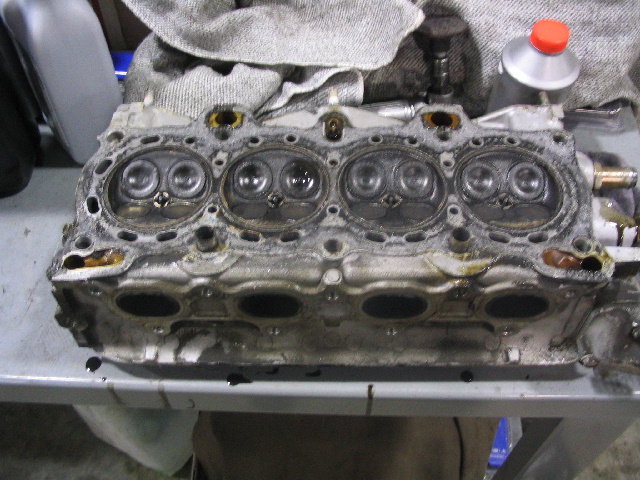

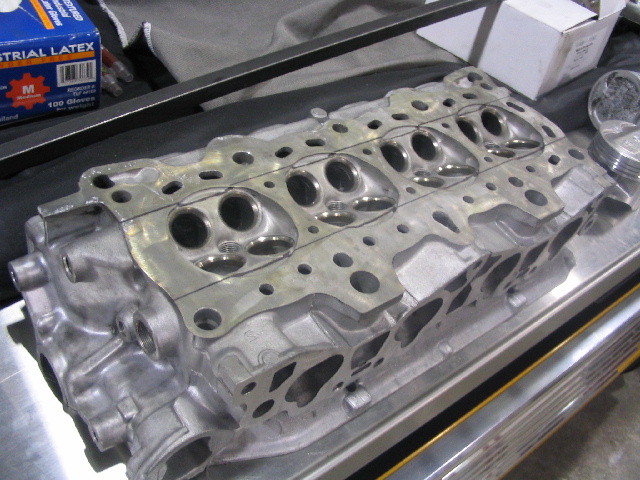

The head was pretty tired as well, full of carbon, exhaust valves were beat to hell.

Nice and black

Cleaned the block with Super clean and some mild degreaser and gave her a quick hone job.

I perfer Ball hones because they leave nicer cross hatch marks.

Standard bore Dohc ZC pistons from ebay. Comes with pins and rings.

Everything dissasembled and cleaned up.

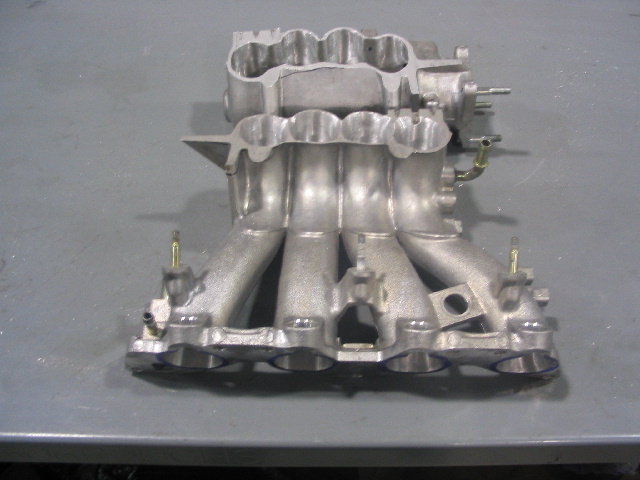

Stock intake manifold being cut in half

Intake manifold chopped in half, you can see how small the runners are.

First thing was cutting the bridge's off on the plenum.

Then grinding them down smooth inside.

As you can see Porting makes a huge mess, so be prepared for a big clean up

Port matching the ports to about the same size as a B16a inlet.

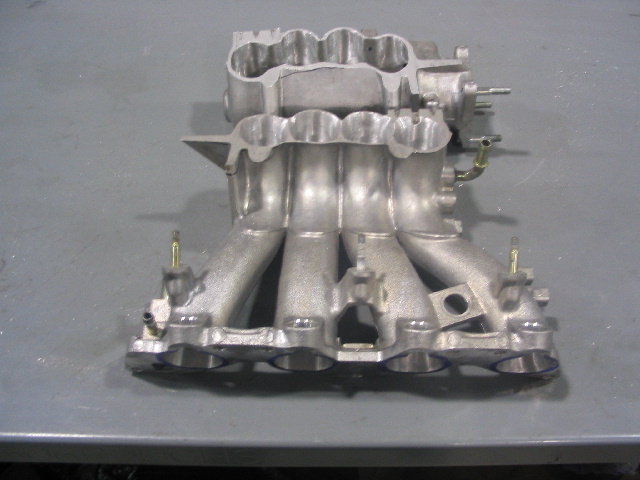

Lower intake opened up big time, I spent several hours porting this damn intake manifold.

I hate porting.. just looking at these pics reminds me how much I hated it. Be sure to where ear plugs when doing this, because after 5 hours of grinding on metal it really gets annoying. All the guys in the shop wanted to kill me

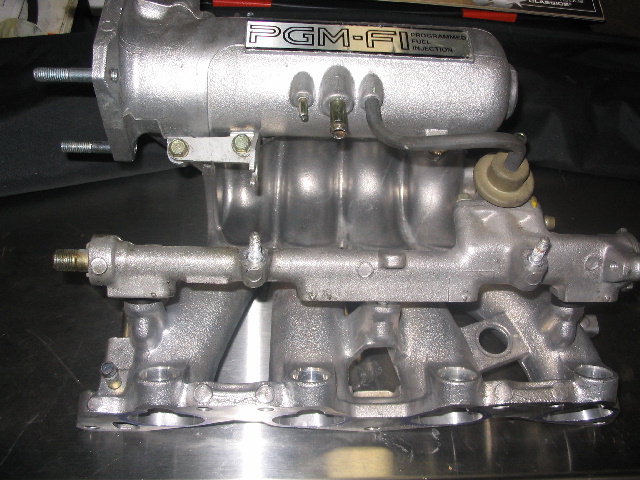

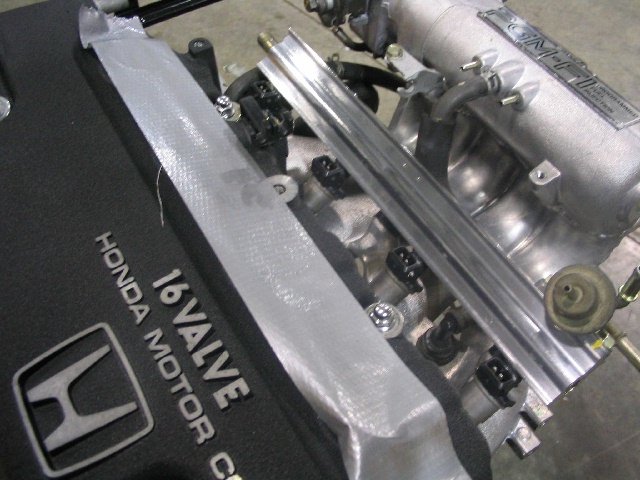

Upper and lower intake all done. I ported the entire length of the runners.

The plenum all ported out (60mm inlet)

Upper and lower attached

Special porting bits I had, I made 1 of the tools, I welded a "whipit" on the end of some 1/4 rod so I could smooth out the insides of the runners after I ported them out. You can get these long carbid bits on tool trucks like snapon/mac/mactco etc. I also recommend using a Electric die grinder because they are easier to control and quieter.

Manifold welded up on the front side.

Can't even see the weld when all the ---- attached

Next was the flywheel, I wanted to take a few pounds off this bitch.

Slapped the bitch on the brake lathe and went to town, took about a little over a hour. But I got 6.5lbs off the backside.

All done, I even did a slow cut on it

The Cylinder head... I wanted to shape the combustion chamber how B18c (gsr) cylinder heads are, this would require tig welding the areas shown above. This would also bump the compression up alot.

I welded up 1 chamber and started freaking out because it was really hard to control the bead. I was unaware that cylinder heads "sweat" when they are heated, so all the oil and ---- comes flowing out of the metal. It made it really hard. So the master aluminum welder Lional did the rest for me. (thanks dude!)

As you can see I ported the ---- out of the head, I had around 10 hours total in the head, I opened up everything.

Exhaust ports all polished up. The head also received a 3way valve grind and resurface.

Intake ports all ported out. Sorry I didnt take to many pics when I was doing the head because I forgot. I was in the "porting zone" lol.. the head came out real nice and I was really happy with it. The ports are all port matched and are about the same size of b16a ports, (maybe slightly larger)

The block with the ZC pistons installed. ZC's have the largest dome on top of the piston compared to any other D-series piston. This really bumps the compression up on a D16a6 block.

Bottom end all cleaned up.. Did I replace the bearings? helll no, lol I couldnt beleive how good they looked I did replace 1 main bearing on the end because it was a little worn. I plastigauged the entire bottom end and it was perfect.

The Delta 272 Camshaft, its basically just a regrind. Delta is about a hour from my house so I picked one up. Pretty dang cheap, 49 bucks!

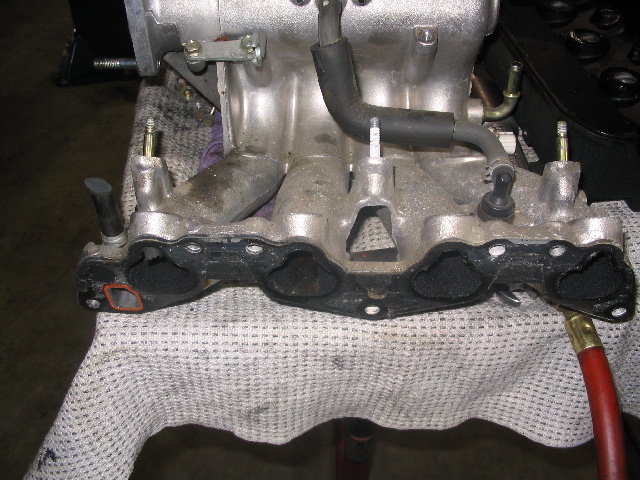

The Exhaust manifold, I compared the ZC/A6/Z6/Y8 manifolds and the ZC was by far the biggest.

ZC on the left, and the A6 on the right. The ZC uses a 4-2-1 design vs the 4-1 like the A6. Gave the mani a coat of high temp flat black.

Since I could not use a "header" I knew that alot of modifactions would have to be done to the stock manifold.

I found a B16a downpipe, and it appeared to have larger pipes, but the exit pipe was really small, just like the ZC. Both measured at 1.5in

I went to ------- town porting this manifold, I really hate porting cast iron more than anything. It stinks, it smells bad and I just overal hate it. Port matched for the most part, but the roof was raised.

Ported the Welds on the downpipe, and slightly enlarged them. Also port matched with the manifold.

Chopped off the shitty stock 1.5in flange and welded on a nice 2.5in pipe w/ 3bolt universal flange.

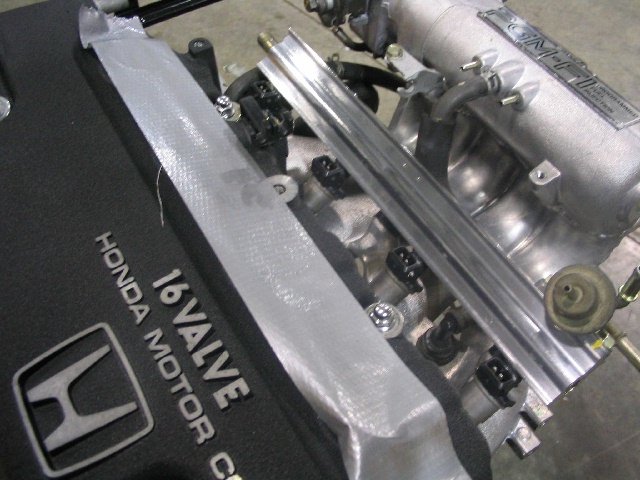

Using a D16z6 Head gasket and a Nayhow mfg Intake manifold gasket (basically the exact same materal as the Hondata IM gasket) It keeps intake temps down big time.

Engine being assembled

Using Prelude H22 345cc injectors on a modified Z6 fuel rail. (these will both be changed later to stock)

Big thanks to Chris (our hybrid forum moderator) for the Bored out D16a6 throttle body. Bore tapered from 60mm to 58. He also gave me a few ideas when doing this project. Thanks again man.

And yes thats a 02 Porsche 911 TT in the background, its the owners

The stock crank pulley on the left, and a very very light D15 crank pulley from a 88 LX. Fits perfect.

This is what screwed me up, I had a idea that if you were to remove the step on the outside of the flywheel (make it flush) so the PP area and the Clutch area were the same it would make the stock clutch bite hard, and hold more power. Kinda like if you look at a B-series flywheel the steps are reverse to d-series. Well this didnt work out, it actually made the clutch slip really bad. It wouldnt hold any power and it was way to easy to engauge. So I pretty much did this backwards. I had the flywheel fixed today (stock step .30 thou)

Engine all ready to go in

All hooked up and installed. The B16a distributor and the nology wires are just temporary. So funny putting a D-series back in my car

Yes I know, I dont have a upper radiator hose clamp, or the radiator doesnt have a mount either. Got a few things to fix

Still got the factory stickers on the upper timing cover

The exhaust system, lol.. a 2.5in cherry bomb (this is also temporary) and yes I know In need to cut those damn bolts for the cage.

I must say its nice to drive my car again, its been about 6 months since shes been on the road. Looks really funny without a intercooler in the front of my car

My tinted lexan sunroof plug I made, it didnt come out as good as I wanted, oh well.

Since my car was sitting for 6 months the damn cage had surface rust all over it, so I spent the night cleaning it all up and painting it flat black for now.

All done, I missed a few spots here and there.. but I'll get it later!

This ALL MOTOR write up was brought to you by HMT biatch!

Ok so how does it run? ehh, not to bad. Pretty much what I expected. I didnt have crazy goals for the thing, I'm not trying to break records or anything like that either. It's definatly faster than a stock ZC. I'd say somwhere inbetween a stock LS and a stock b16a? I was hoping to get about a 40whp gain from all this ---- I did. From my calculations the engine should be 14.1 c/r, whats crazy the thing has been pretty easy to tune so far. I havent had any issues with it pinging at all. We are all about to go to the dyno next saturday so we'll see if my *** dyno is accurate. I say 135ish....

Price list

D16a6 Free

ZC Pistons 140

z6 Head gasket 30

IM heat shield gasket 30

Delta Cam 50

Flywheel resurface 30

Valve Grind (buddy buddy deal) 150

Porting bits 30

I got around 500 bucks total into this project, however I have tons of labor in this project. Probably more hours in labor than I have ever done on one single project. Sadly it will be the lowest producing HP project that I spent the most time on.. Haha

::cliff notes::

40whp for 500 bucks is pretty decent if ya ask me.. a 500 dollar HMT kit would probably make double that.

ok I'm ------- tired

::EDIT VIDEO:: right click save as WMV

http://www.draglab.com/media/a6.wmv

Anyways Onto the Mighty D project, lol

Starting off with a 88 D16a6 from a Civic SI (150k miles) I recently did a ZC swap in for a customer. Putting out a blistering 105hp at the crank maybe 90ish whp.

Engine was pretty dirty since it was pretty high milage, I went ahead and dissasembled the engine.

Stock Intake manifold all carboned up

The head was pretty tired as well, full of carbon, exhaust valves were beat to hell.

Nice and black

Cleaned the block with Super clean and some mild degreaser and gave her a quick hone job.

I perfer Ball hones because they leave nicer cross hatch marks.

Standard bore Dohc ZC pistons from ebay. Comes with pins and rings.

Everything dissasembled and cleaned up.

Stock intake manifold being cut in half

Intake manifold chopped in half, you can see how small the runners are.

First thing was cutting the bridge's off on the plenum.

Then grinding them down smooth inside.

As you can see Porting makes a huge mess, so be prepared for a big clean up

Port matching the ports to about the same size as a B16a inlet.

Lower intake opened up big time, I spent several hours porting this damn intake manifold.

I hate porting.. just looking at these pics reminds me how much I hated it. Be sure to where ear plugs when doing this, because after 5 hours of grinding on metal it really gets annoying. All the guys in the shop wanted to kill me

Upper and lower intake all done. I ported the entire length of the runners.

The plenum all ported out (60mm inlet)

Upper and lower attached

Special porting bits I had, I made 1 of the tools, I welded a "whipit" on the end of some 1/4 rod so I could smooth out the insides of the runners after I ported them out. You can get these long carbid bits on tool trucks like snapon/mac/mactco etc. I also recommend using a Electric die grinder because they are easier to control and quieter.

Manifold welded up on the front side.

Can't even see the weld when all the ---- attached

Next was the flywheel, I wanted to take a few pounds off this bitch.

Slapped the bitch on the brake lathe and went to town, took about a little over a hour. But I got 6.5lbs off the backside.

All done, I even did a slow cut on it

The Cylinder head... I wanted to shape the combustion chamber how B18c (gsr) cylinder heads are, this would require tig welding the areas shown above. This would also bump the compression up alot.

I welded up 1 chamber and started freaking out because it was really hard to control the bead. I was unaware that cylinder heads "sweat" when they are heated, so all the oil and ---- comes flowing out of the metal. It made it really hard. So the master aluminum welder Lional did the rest for me. (thanks dude!)

As you can see I ported the ---- out of the head, I had around 10 hours total in the head, I opened up everything.

Exhaust ports all polished up. The head also received a 3way valve grind and resurface.

Intake ports all ported out. Sorry I didnt take to many pics when I was doing the head because I forgot. I was in the "porting zone" lol.. the head came out real nice and I was really happy with it. The ports are all port matched and are about the same size of b16a ports, (maybe slightly larger)

The block with the ZC pistons installed. ZC's have the largest dome on top of the piston compared to any other D-series piston. This really bumps the compression up on a D16a6 block.

Bottom end all cleaned up.. Did I replace the bearings? helll no, lol I couldnt beleive how good they looked I did replace 1 main bearing on the end because it was a little worn. I plastigauged the entire bottom end and it was perfect.

The Delta 272 Camshaft, its basically just a regrind. Delta is about a hour from my house so I picked one up. Pretty dang cheap, 49 bucks!

The Exhaust manifold, I compared the ZC/A6/Z6/Y8 manifolds and the ZC was by far the biggest.

ZC on the left, and the A6 on the right. The ZC uses a 4-2-1 design vs the 4-1 like the A6. Gave the mani a coat of high temp flat black.

Since I could not use a "header" I knew that alot of modifactions would have to be done to the stock manifold.

I found a B16a downpipe, and it appeared to have larger pipes, but the exit pipe was really small, just like the ZC. Both measured at 1.5in

I went to ------- town porting this manifold, I really hate porting cast iron more than anything. It stinks, it smells bad and I just overal hate it. Port matched for the most part, but the roof was raised.

Ported the Welds on the downpipe, and slightly enlarged them. Also port matched with the manifold.

Chopped off the shitty stock 1.5in flange and welded on a nice 2.5in pipe w/ 3bolt universal flange.

Using a D16z6 Head gasket and a Nayhow mfg Intake manifold gasket (basically the exact same materal as the Hondata IM gasket) It keeps intake temps down big time.

Engine being assembled

Using Prelude H22 345cc injectors on a modified Z6 fuel rail. (these will both be changed later to stock)

Big thanks to Chris (our hybrid forum moderator) for the Bored out D16a6 throttle body. Bore tapered from 60mm to 58. He also gave me a few ideas when doing this project. Thanks again man.

And yes thats a 02 Porsche 911 TT in the background, its the owners

The stock crank pulley on the left, and a very very light D15 crank pulley from a 88 LX. Fits perfect.

This is what screwed me up, I had a idea that if you were to remove the step on the outside of the flywheel (make it flush) so the PP area and the Clutch area were the same it would make the stock clutch bite hard, and hold more power. Kinda like if you look at a B-series flywheel the steps are reverse to d-series. Well this didnt work out, it actually made the clutch slip really bad. It wouldnt hold any power and it was way to easy to engauge. So I pretty much did this backwards. I had the flywheel fixed today (stock step .30 thou)

Engine all ready to go in

All hooked up and installed. The B16a distributor and the nology wires are just temporary. So funny putting a D-series back in my car

Yes I know, I dont have a upper radiator hose clamp, or the radiator doesnt have a mount either. Got a few things to fix

Still got the factory stickers on the upper timing cover

The exhaust system, lol.. a 2.5in cherry bomb (this is also temporary) and yes I know In need to cut those damn bolts for the cage.

I must say its nice to drive my car again, its been about 6 months since shes been on the road. Looks really funny without a intercooler in the front of my car

My tinted lexan sunroof plug I made, it didnt come out as good as I wanted, oh well.

Since my car was sitting for 6 months the damn cage had surface rust all over it, so I spent the night cleaning it all up and painting it flat black for now.

All done, I missed a few spots here and there.. but I'll get it later!

This ALL MOTOR write up was brought to you by HMT biatch!

Ok so how does it run? ehh, not to bad. Pretty much what I expected. I didnt have crazy goals for the thing, I'm not trying to break records or anything like that either. It's definatly faster than a stock ZC. I'd say somwhere inbetween a stock LS and a stock b16a? I was hoping to get about a 40whp gain from all this ---- I did. From my calculations the engine should be 14.1 c/r, whats crazy the thing has been pretty easy to tune so far. I havent had any issues with it pinging at all. We are all about to go to the dyno next saturday so we'll see if my *** dyno is accurate. I say 135ish....

Price list

D16a6 Free

ZC Pistons 140

z6 Head gasket 30

IM heat shield gasket 30

Delta Cam 50

Flywheel resurface 30

Valve Grind (buddy buddy deal) 150

Porting bits 30

I got around 500 bucks total into this project, however I have tons of labor in this project. Probably more hours in labor than I have ever done on one single project. Sadly it will be the lowest producing HP project that I spent the most time on.. Haha

::cliff notes::

40whp for 500 bucks is pretty decent if ya ask me.. a 500 dollar HMT kit would probably make double that.

ok I'm ------- tired

::EDIT VIDEO:: right click save as WMV

http://www.draglab.com/media/a6.wmv

#6

whatever happened to the wheeze 2 that was on the front page? we never saw anything about that other then the front page pic with some dude blowing fire all over an engine block haha.

abaz whats up with that?

abaz whats up with that?

Thread

Thread Starter

Forum

Replies

Last Post

beerbongskickass

General Discussion

70

05-30-2007 03:18 PM

Yeah jeff what happened to this motor :P

Yeah jeff what happened to this motor :P